ABS PVC Formwork For Concrete Construction Plastic Formwork

Introducing our innovative Plastic Formwork for Concrete, the ultimate solution for all your construction needs. Designed specifically for creating concrete columns, pillars, walls, plinths, and foundations directly onsite, our formwork system is a game-changer in the construction industry.

Our interlocking and modular systems of reusable plastic formwork are perfect for building a wide variety of concrete structures that are both simple and efficient. Made from high-quality plastic, our formwork is lightweight and can be easily handled manually, allowing for quick and hassle-free installation. Unlike traditional formwork materials, our plastic formwork leaves no blemishes or discoloration on the concrete, ensuring a flawless finish every time.

One of the standout features of our Plastic Formwork for Concrete is its cost-effectiveness. By choosing our PVC formwork, you can save significantly on your construction budget compared to other material formwork systems. This makes it an ideal choice for both small-scale projects and large construction sites.

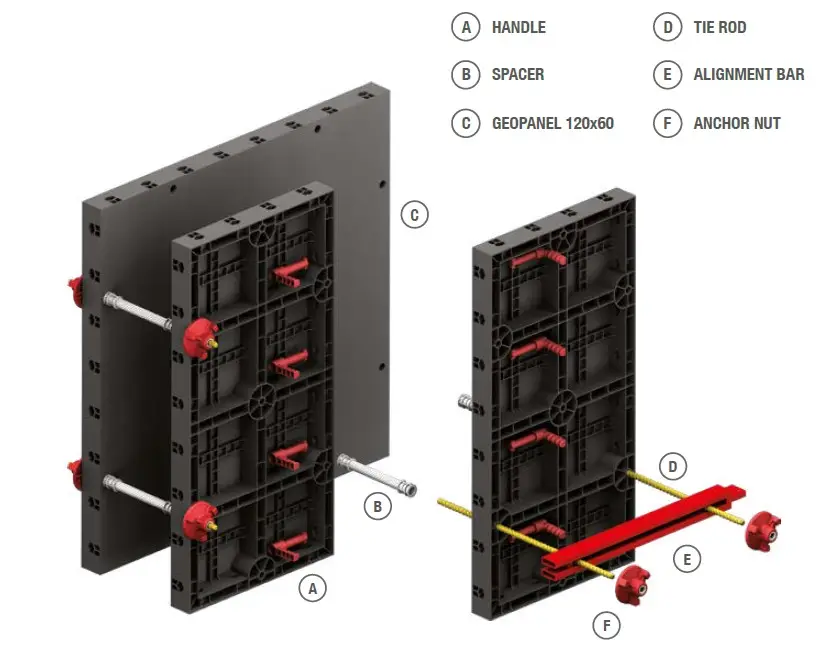

The ease of use is further enhanced by the design of our formwork. It can be carried by a single person without the need for cranes or heavy lifting equipment, making it accessible for any construction team. Erection is a breeze, requiring just a simple 90-degree rotation of the erection handle, which ensures smooth joints between panels for a seamless construction process.

Whether you are looking for reliable wall formwork or plastic column formwork, our Plastic Formwork for Concrete is the perfect choice for your next project. Experience the benefits of modern construction technology with our durable, efficient, and budget-friendly formwork solutions. Transform your construction process today!

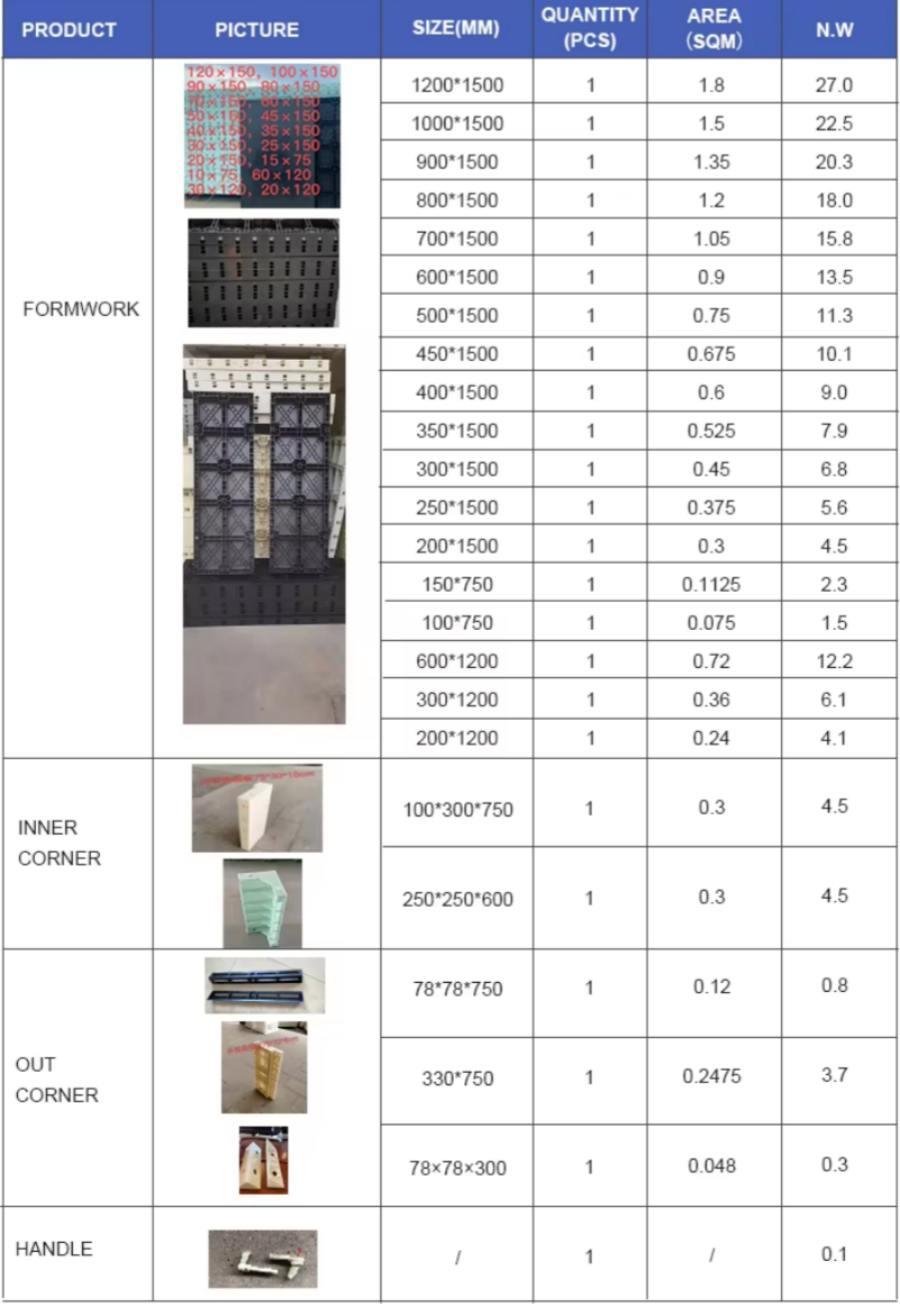

|

Name |

plastic construction formwork |

| Size | 1220*2440mm or customized |

| Thickness | 9-20mm |

| Density | 0.5-0.95g/cm3 |

| Color | grey, blue, green, customized |

| Surface |

high glossy |

| Certificate | SGS |

Plastic formwork are suitable to realize concrete columns, pillars, walls, plinths, and foundations directly onsite. Interlocking and modular systems of re-usable plastic formwork are used to build widely variable, but relatively simple, concrete structures. The panels are lightweight and very robust. They are especially suited for similar structure projects and low-cost,mass housing schemes. Their modularity satisfies every construction and planning needs:columns and pillars of different shapes anddimensions,walls and foundations of different thickness and height.

Formwork Features:

1. Long lifespan& Cost effective -- Plastic formwork can be reused over 100 times, where Plywood can only be reused 3 to 5 times. Therefore the Plastic is more cost effective.

2. Waterproof -- As the nature of plastic material. It's imputrescible and rustless, especially suitable for underground and watery circumstance.

3. Interlocking Design -- No release agent needed, good effect of demolding.

4. Easy deassembly -- The plastic formwork will be separated easily from concrete.

5. Simple Installation -- Light weight and safe to handle, easy cleaning and very robust.

6. High Quality -- Abrasion resistance, excellent mechanical property, best impermeability.

7. Recycable -- Waste scrap molding board could be recycled.

Packing: All items will be packed by pallet / belt / wooden pallet / steel pallet / high standard steel pallet / nylon bag /carton box.

1. who are we?

We are based in Tianjin,China,start from 2014,sell to Oceania(45.00%),Mid East(13.00%),Mid East(13.00%),Eastern Asia(8.00%),South Asia(8.00%),Eastern Asia(8.00%),Central America(6.00%),Southeast Asia(6.00%),South America(6.00%),Central America(6.00%),Southeast Asia(6.00%),Northern Europe(5.00%),Northern Europe(5.00%),Africa(3.00%),Africa(3.00%). There are total about 5-10 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Steel Props, Scaffoldings, Scaffolding Accessories, Formwork, Formwork Accessories;

4. why should you buy from us not from other suppliers?

High quality; Competitive price; Short delivery time; Satisfied service; Manufactured according to different standards;

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese

Diana yang

Wechat:008615946123613

WhatsApp: 008615946123613

Email: diana@rainbowsteel.cn

Web: www.tjrainbowsteel.com