Best quality Galvnized Steel Pipe - Round Steel Screw Guard Tubing for Solar Tracking System – Rainbow

Best quality Galvnized Steel Pipe - Round Steel Screw Guard Tubing for Solar Tracking System – Rainbow Detail:

Introduction:

Tianjin Rainbow Steel has put emphasis over the administration, the introduction of talented staff, strengthen the construction of team building, attempting hard to boost the standard and liability consciousness of personnel customers. Our company has successfully attained IS9001 Certification and European CE Certification . We often concertrating on creating new creative solutions to meet requests from our customers all over the world.

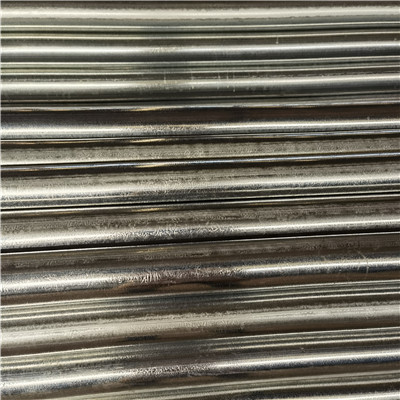

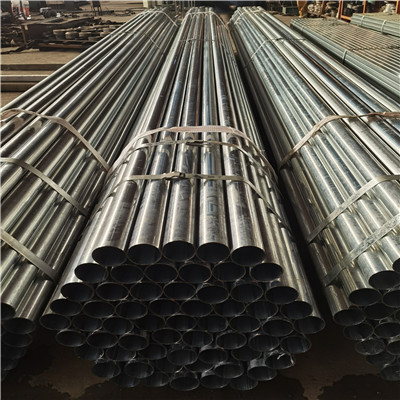

Welded steel pipes with hot dip coating or electric-galvanized coating on the surface of steel pipes. Galvanizing coating will increase the corrosion resistance of steel pipes and prolong their service life. Galvanized pipes are widely used, not only as pipelines for water, gas, oil and other general low-pressure fluids, but also as oil pipes . galvanized coating pipes will also be used as scaffolding frame, solar mounting system steel frames, steel pole frames, and other related steel structures.

Specification:

| Secondary or not | Non-secondary |

| Alloy or not | Non-alloy |

| Technique | ERW, hot rolled or cold rolled |

| Standard | BS 1387, BS EN 39, GB/T 3091, ASTM A53, JIS G3444, etc. |

| Grade/Material | 10#, 20#, 45#, Q195, Q235, Q345, 16Mn, ST 37.4, etc. |

| Place of origin | Tianjin, China(Mainland) |

| Certifications | ISO 9001:2008, BV, SGS, ABS |

| Production capacity | 3500 ton/week |

| Section shape | Round |

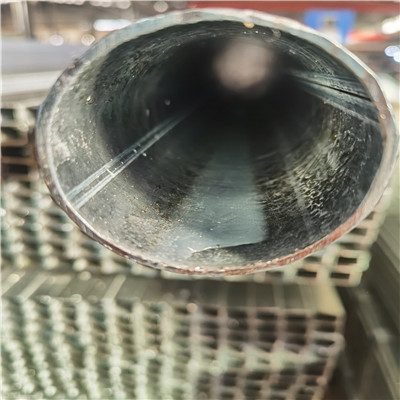

| Outer diameter | 20-325mm |

| Wall thickness | 1.0-25mm |

| Length | 2-12m, or cut as request. |

| Technique tolerance | OD: +/-1mm, WT: +/-0.5mm, L: +/-20mm |

| Surface treatment | Galvanized, painted, oiled, printed or powder coated |

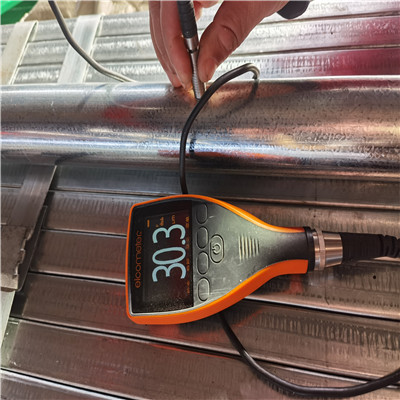

| Zinc coated | pre-galvanized, 80-120 g/m2; hot dip galvanized, 230-500 g/m2 |

| Colour | Silver, black or painted as request |

| End of pipe | Plain?burred,beveled, threaded |

| Trade term | FOB Tianjin China, CIF, C&F |

| Loading Port | Tianjin Xingang Port, China |

| Package | 1.Big OD: in bulk; 2.Small OD: in bundles, packed by steel strips; 3. Waterproof package with plastic cloth; 4.Standard export package; 5.According to customers |

Inspection :

Flattening and Flaring Test:

Flattening Test-–A test 4 to 6 in.(100-150mm)in length shall be flattened between parallel plates with the weld 90°from the direction of applied force(at the point of maximum bending)untillopposite walls of the tubing meet.Except as allowed in S6.2.1, no opening in the weld shall take place until the distance between the plates is less than two thirds of original outside diameter of the tubing,but in no case less than five times the thickness of the tubing wall.Evidence of lamination or burn material shall not develop during the flattening process, and the weld shall not show injurious defects. S6.2.1 when low D- to -t ratio tubing is tested, because the strainimposed due to geometry is unreasonably high on the inside surface at the six and twelve o’clock locations,cracks at these locations shall not be cause for rejection if the D-to -t ratio is less than 10.

Flaring Test—A section of tube approximately 4in.(100mm) in length shall stand being flared with a tool having a 60° included angle until the tube at the mouth of the flare has been expanded 15% of the inside diameter, without cracking or showing flawns.S 6.4 in order to properly evaluateweld quality ,the producer at his option may normalize the test specimen prior to testing. S6.5 Number of tests and retests:S6.5.1 Two Falttening and two flaring tests shallbe made from each lot as specified. Each tested specimen shall conform to the respective rtequirement(see note S1). S 6.5.2 if the results of the testing do not conform to the requirements,retests shall be made on four additional specimens,each of which shall conform to the respective requirement.

Packing :

Exhibition Show:

Welcome to visit us !

Tianjin Rainbow Steel, Tianjin China

Product detail pictures:

Related Product Guide:

Steel Deep Processing

4 kinds of methods of steel structure interlayer

With our loaded encounter and considerate services, we have now been recognized as a trustworthy supplier for lots of worldwide consumers for Best quality Galvnized Steel Pipe - Round Steel Screw Guard Tubing for Solar Tracking System – Rainbow , The product will supply to all over the world, such as: Cyprus, Oslo, Netherlands, We've been always creating new technology to streamline the production, and give products with competitive prices and high quality! Customer satisfaction is our priority! You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We are going to present our best service to satisfy all your needs! Remember to contact us right away!

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.