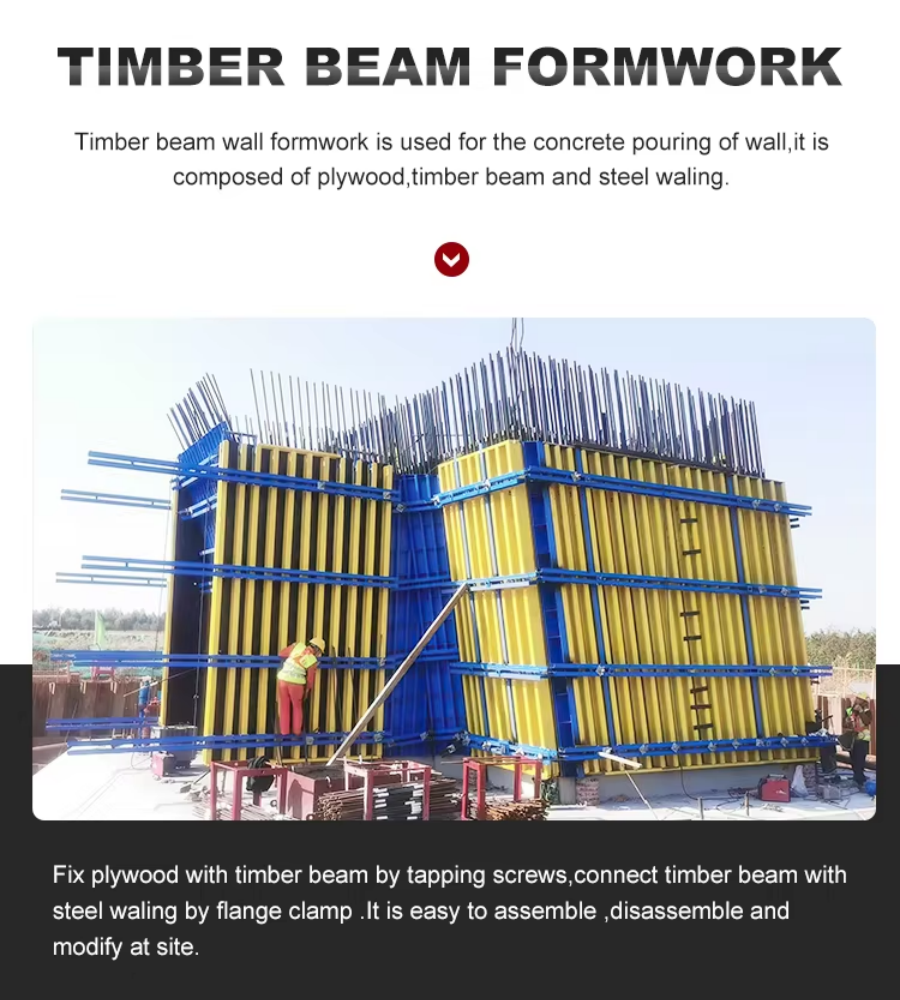

Doka H20 Wood Timber Beam Concrete Plywood Formwork System

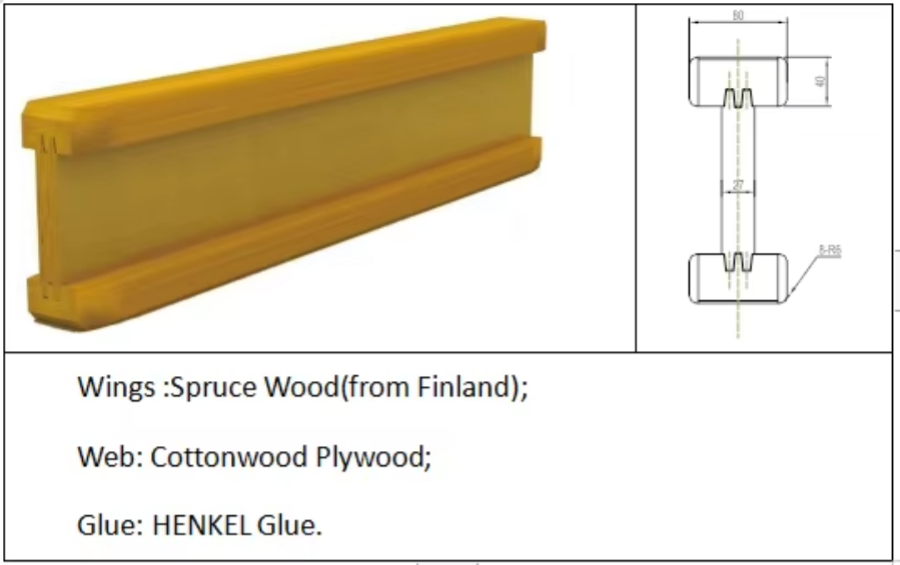

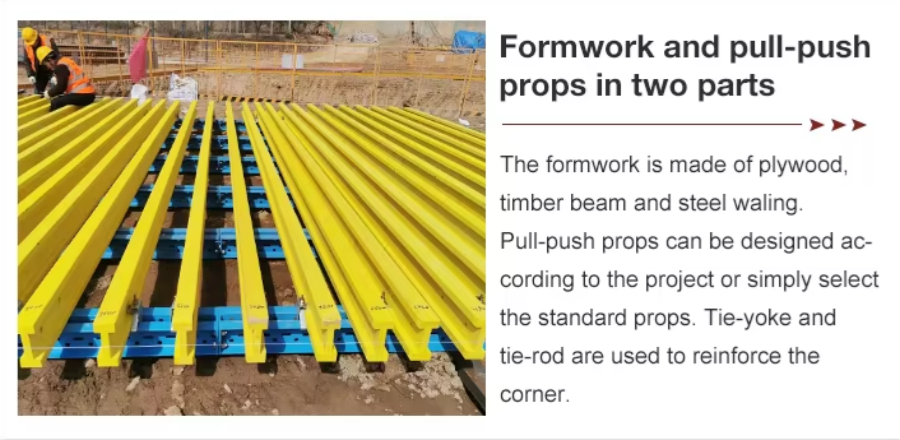

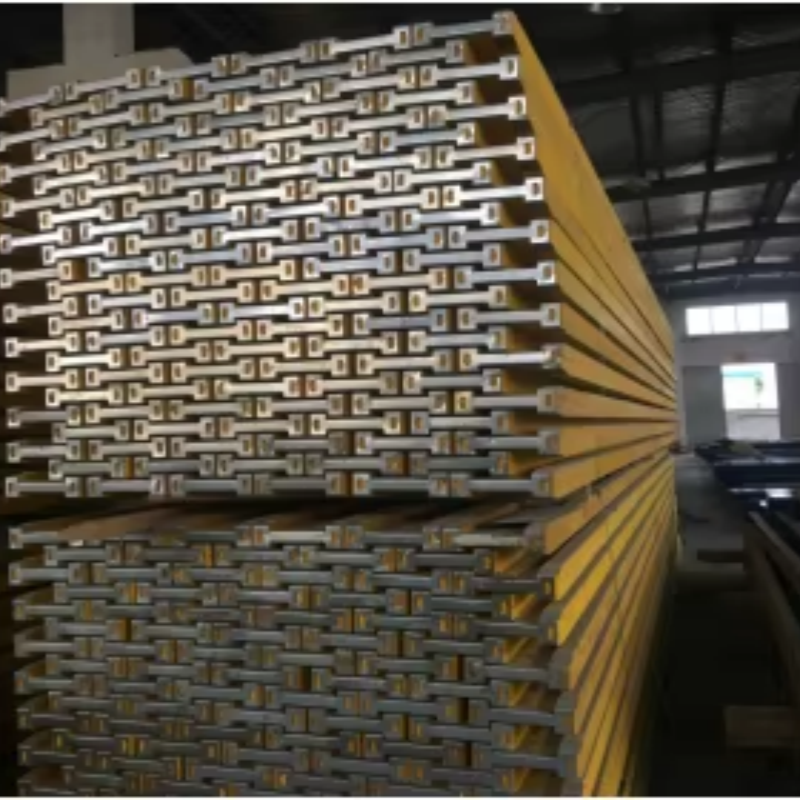

Introducing the Formwork H20 Timber Beam – the ultimate solution for your construction needs. Also known as H20 Wood Beam, I Joist, I Beam, Wood H Beam, or Wood Girder, this innovative product is designed to meet the demands of modern construction projects. Whether you are working with concrete formwork, concrete plywood formwork, or Doka formwork systems, our H20 Timber Beam is the perfect choice for ensuring structural integrity and efficiency.

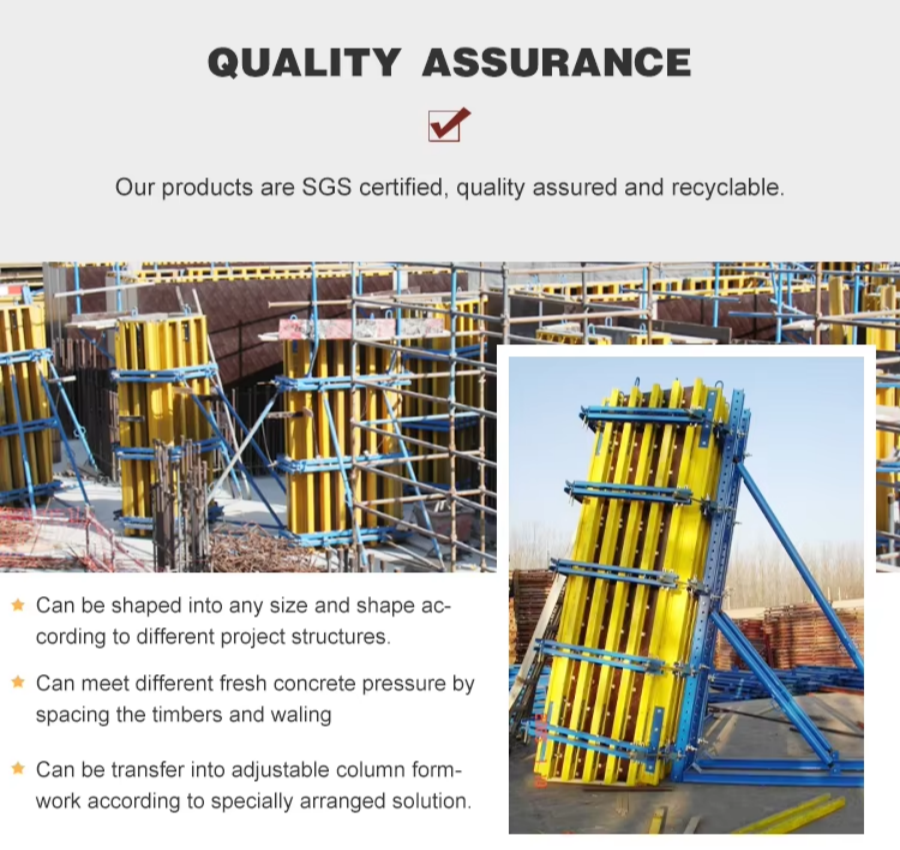

Crafted from engineered spruce wood, the Formwork H20 Timber Beam is not only the strongest but also the lightest formwork beam available on the market. This unique combination of strength and lightweight design makes it ideal for use in various applications, including formwork systems, construction system parts, falsework systems, timber structures, and other bearing structures.

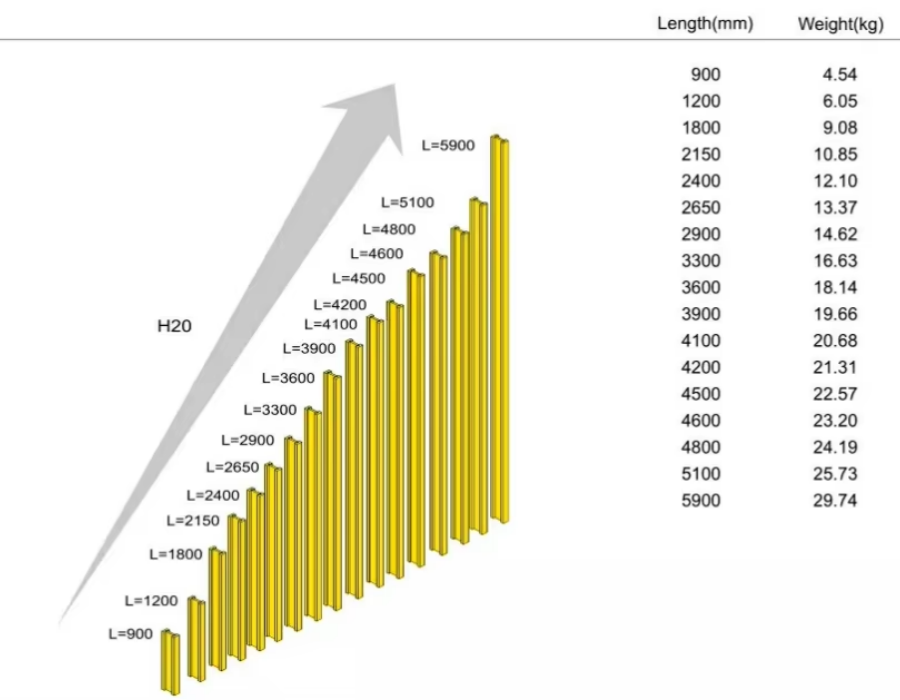

Our Formwork H20 Timber Beams are produced in a range of standard lengths, allowing for versatility and adaptability in any project. The engineered design ensures that these beams can withstand heavy loads while maintaining their shape and performance over time. This reliability is crucial for contractors and builders who require materials that can keep up with the rigorous demands of construction.

Incorporating the Formwork H20 Timber Beam into your project not only enhances safety and stability but also streamlines the construction process, saving you time and resources. With its exceptional performance and durability, this product is a must-have for any construction professional looking to elevate their work.

Choose the Formwork H20 Timber Beam for your next project and experience the difference that quality engineering and design can make. Trust in a product that stands the test of time and delivers results you can rely on.

|

Product Name

|

H20 Beam / h 20 Wooden Beam Formwork for hydraulic automatic climbing formwork

|

|||

|

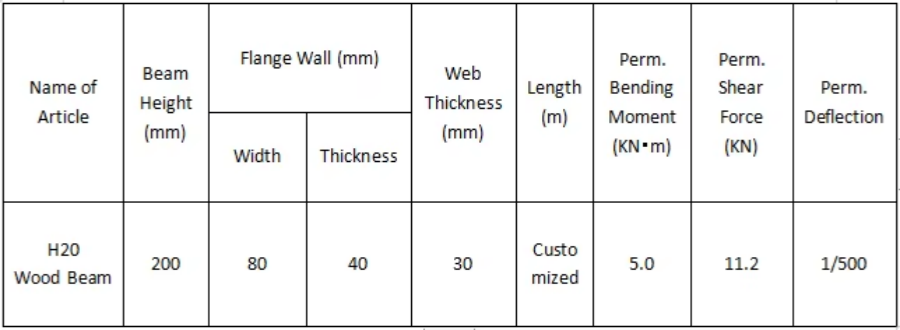

Technical Specification

|

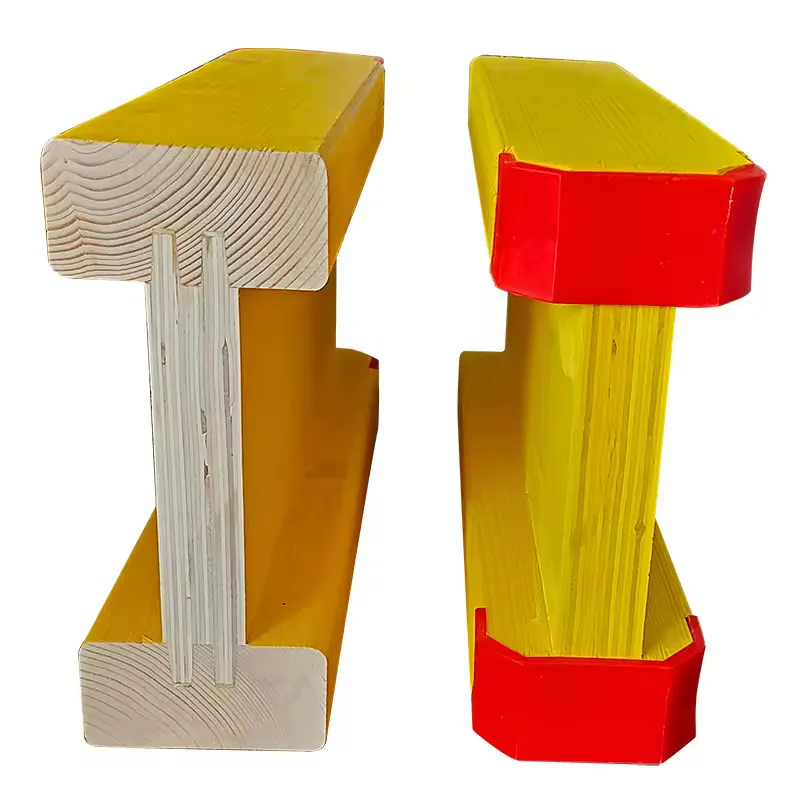

Flange: Radiate pine LVL from New Zealand

Web: Poplar core plywood Glue: WBP glue Weight: around 5.0 kg/m Available length (m): 1.5, 1.9, 2.45, 2.75, 2.90, 3.00, 3.30, 3.60, 3.90, 4.50, 4.90, 5.90 etc. or customized |

|||

|

Features

|

* Flange is made from imported radiate pin LVL, Finger-jointed into the web* Web is made from poplar core plywood with Melamine WBP glue

* Two ends of each beam can be sealed with protective caps to protect them from moisture, reduce damage and increase service life * Yellow water proof painting * Monitoring as per EN13377 standard |

|||

|

Packing

|

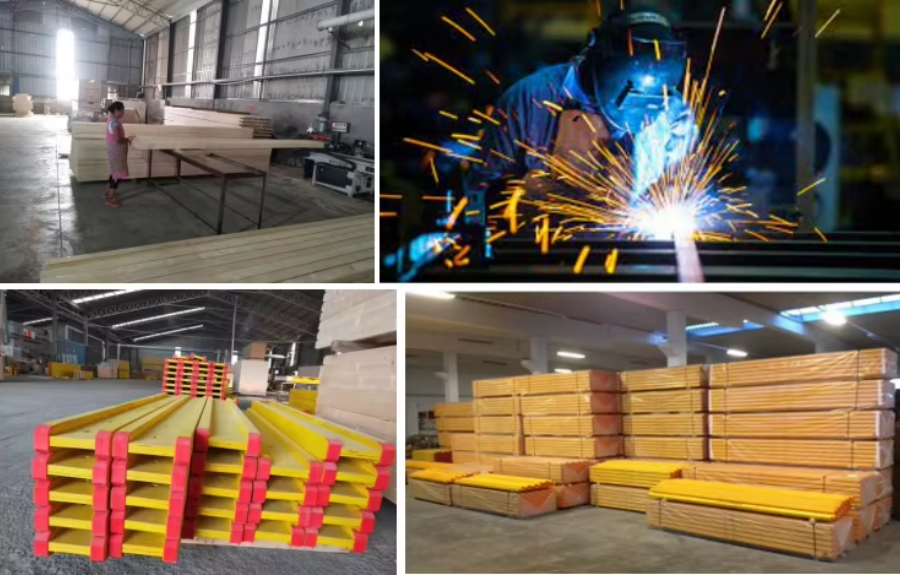

Standard exporting package( bottom is pallet, covered with plastic film, around is carton, strengthen by steel tape with 3*6

|

|||

|

Size Available

|

length:3000-6000mm, width:70-300mm

|

|||

|

Surface

|

yellow waterproof painting or as per request

|

|||

●Finger jointing of the flange and web,the strength of timber beam is highly improved. Max shearing force failure load:40KN.

●Well treated to prevent from water penetration or erosion, so the service life maximally extended. Normally, timber beam H20 can be used for 4 to 5 years, the exact using time would depend on maintenance & storage.

●Robust caps at the end of the girders protect against damages.

Packing Details : Packing strip, package box, steel pallet, or according to client's request

Delivery Details : Generally it is 5-30 days, it is according to quantity

Port : Tianjin

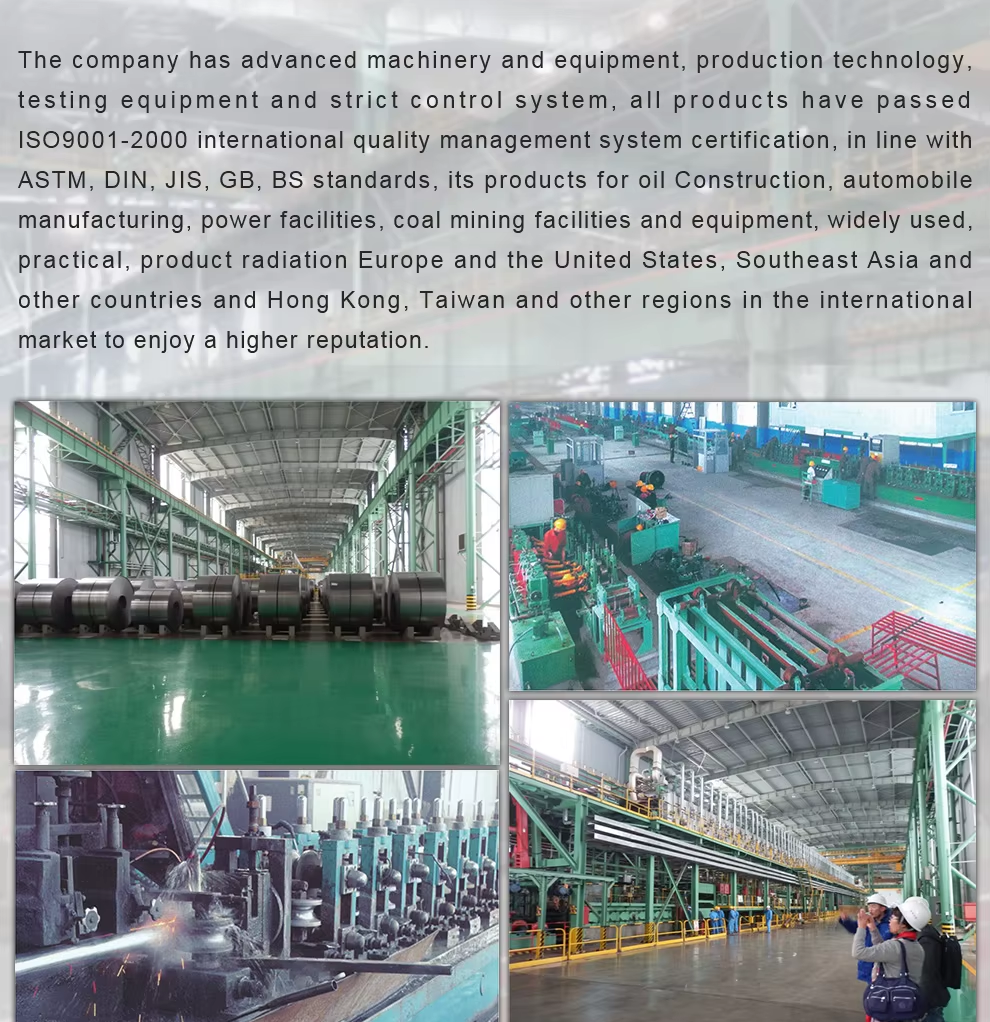

1. who are we?

We are based in Tianjin,China,start from 2014,sell to Oceania(45.00%),Mid East(13.00%),Mid East(13.00%),Eastern Asia(8.00%),South Asia(8.00%),Eastern Asia(8.00%),Central America(6.00%),Southeast Asia(6.00%),South America(6.00%),Central America(6.00%),Southeast Asia(6.00%),Northern Europe(5.00%),Northern Europe(5.00%),Africa(3.00%),Africa(3.00%). There are total about 5-10 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Steel Props, Scaffoldings, Scaffolding Accessories, Formwork, Formwork Accessories;

4. why should you buy from us not from other suppliers?

High quality; Competitive price; Short delivery time; Satisfied service; Manufactured according to different standards;

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese

Diana yang

Wechat:008615946123613

WhatsApp: 008615946123613

Email: diana@rainbowsteel.cn

Web: www.tjrainbowsteel.com