Fast Installation Building Construction Concrete Timber Beam Formwork for Concrete Slab

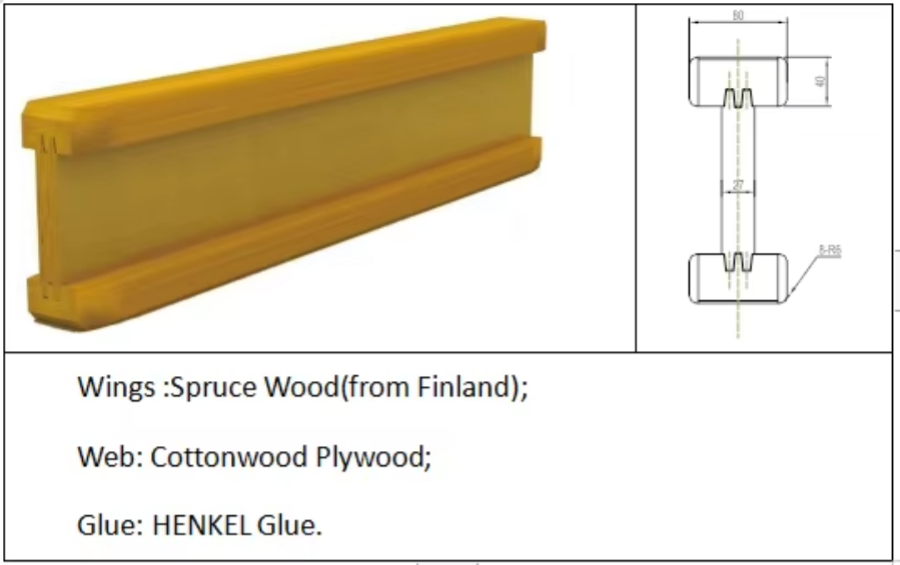

Introducing the H20 Timber Beam Formwork – the ultimate solution for your concrete formwork needs. Crafted in our state-of-the-art woodwork shop, our H20 Timber Beams are produced using a first-class production line, ensuring exceptional quality and durability. With a remarkable daily output of 3000 meters, we are equipped to meet the demands of any large-scale construction project.

Our H20 Timber Beams are designed with versatility in mind. Standard holes can be punched on both ends, allowing for easy customization and length adjustments during construction. Whether you require beams of specific lengths or need to extend them on-site, our team can tailor the wooden beams to fit your exact specifications.

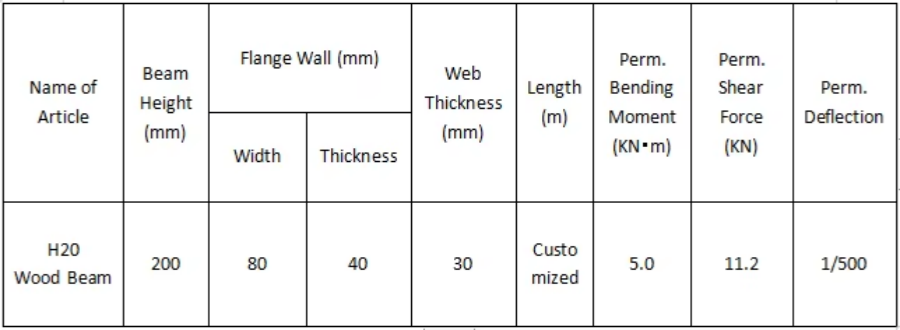

The H20 Timber Beam is a crucial component of the wooden formwork system, widely utilized in various engineering applications. Each beam features finger jointing of the flange and web, significantly enhancing its strength. With a maximum shearing force failure load of 40KN, you can trust that our timber beams will provide the support you need for your concrete projects.

To ensure longevity, our timber beams are meticulously treated to prevent water penetration and erosion, extending their service life to an impressive 4 to 5 years, depending on maintenance and storage conditions. Additionally, robust caps at the ends of the girders protect against damages, ensuring that your investment remains intact throughout the construction process.

Choose H20 Timber Beam Formwork for a reliable, durable, and customizable solution for your concrete formwork needs. Experience the difference that high-quality wooden beams can make in your construction projects today!

|

Product Name |

Fast Installation Building Construction Concrete Timber Beam Formwork for Concrete Slab | |||

| Technical Specification |

Flange: Radiate pine LVL from New Zealand |

|||

| Features |

* Flange is made from imported radiate pin LVL, Finger-jointed into the web* Web is made from poplar core plywood with Melamine WBP glue |

|||

| Packing | Standard exporting package( bottom is pallet, covered with plastic film, around is carton, strengthen by steel tape with 3*6 | |||

| Size Available | length:3000-6000mm, width:70-300mm | |||

| Surface | yellow waterproof painting or as per request | |||

Disassemble formwork can be assembled into a shape that fits the drawings, completely covering the building without the need for secondary treatment of the gaps between the formwork and the structure on site.

The Disassemble Formwork system is convenient to assemble and disassemble, flexible to use, and easy to assemble and disassemble on site.

1. who are we?

We are based in Tianjin,China,start from 2014,sell to Oceania(45.00%),Mid East(13.00%),Mid East(13.00%),Eastern Asia(8.00%),South Asia(8.00%),Eastern Asia(8.00%),Central America(6.00%),Southeast Asia(6.00%),South America(6.00%),Central America(6.00%),Southeast Asia(6.00%),Northern Europe(5.00%),Northern Europe(5.00%),Africa(3.00%),Africa(3.00%). There are total about 5-10 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Steel Props, Scaffoldings, Scaffolding Accessories, Formwork, Formwork Accessories;

4. why should you buy from us not from other suppliers?

High quality; Competitive price; Short delivery time; Satisfied service; Manufactured according to different standards;

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese

Diana yang

Wechat:008615946123613

WhatsApp: 008615946123613

Email: diana@rainbowsteel.cn

Web: www.tjrainbowsteel.com