Featured Products

-

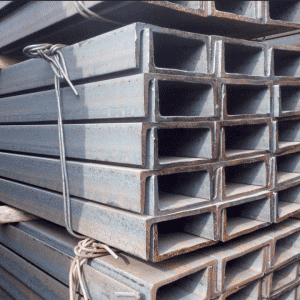

Galvanized Steel Beam Galvanised Steel Solutions

Main features: large pressure, long support time, easy to install and not easy to deform.

Main applications: it is mainly used in mine roadway, secondary support of mine roadway and support of tunnel through mountain.

U-shaped steel is widely used at home and abroad as the main shaped steel for manufacturing tunnel collapsible metal supports.

-

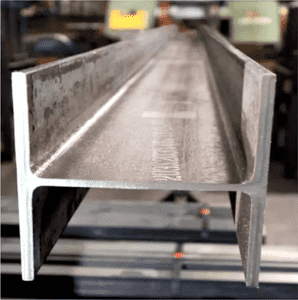

Hot Dip Galvanized Steel U Beam / PFC (Parallel Flange Channels) – Merchant Bar

Main features: large pressure, long support time, easy to install and not easy to deform.

Main applications: it is mainly used in mine roadway, secondary support of mine roadway and support of tunnel through mountain.

U-shaped steel is widely used at home and abroad as the main shaped steel for manufacturing tunnel collapsible metal supports.

-

Channel H Steel H Beam Steel Hot Rolled Iron H Beam

H Beams come in different shapes and sizes. A construction beam is a structural element that bears load by resisting bending from downward forces. Its horizontal span is much broader than its width or depth. Beams are characterized by their profile, length and material.

-

I Beam Sheet Carbon Steel H Beam Profile

H Beams come in different shapes and sizes. A construction beam is a structural element that bears load by resisting bending from downward forces. Its horizontal span is much broader than its width or depth. Beams are characterized by their profile, length and material.

-

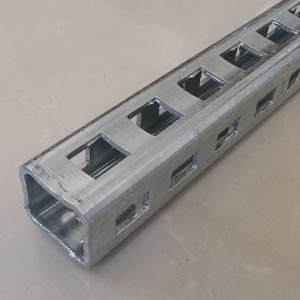

Pipe with Laser Holing

Precision Process on Steel and iron is to process all kinds of raw steel plates, pipes and wires into products that can be directly used by users by cutting, straightening, flattening, pressing, hot rolling, cold rolling, stamping and other Steel deep processing.

-

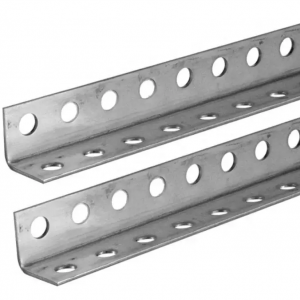

Precision Process on Steel-Iron Angle Hoing & Cutting

Deep processing of iron and steel is to process all kinds of raw steel plates, pipes and wires into products that can be directly used by users by cutting, straightening, flattening, pressing, hot rolling, cold rolling, stamping and other production processes.

-

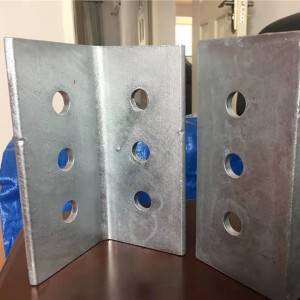

Precision Process on Steel-Steel Angle Hoing & Cutting

Solid Base Angle Bar have been designed to support brickwork over windows & doors. The brickwork, mortar and lintel work together to form a composite beam with exceptional strength and load-carrying capacity. Hot dip galvanized lintels are 40% lighter than solid lintels (and 40% easier to carry) with a high strength to weight ratio.

-

Precision Process on Steel-I Beam with punched holes

H Beams come in different shapes and sizes. I Beam with punched holes is a structural element that bears load by resisting bending from downward forces. Its horizontal span is much broader than its width or depth. Beams are characterized by their profile, length and material.The most common types resemble a Capital I or a Capital H.

-

Precision Process on Steel-Galvanized steel T BAR

Galvanized T Bar is a type of steel cast into a T shape. Because its section and the English letter “T” the same name.

-

Precision Process on Steel-Changed from round pipe, then laser holing

Precision Process on Steel and iron is to process all kinds of plates, pipes and wires in the original state of iron and steel into products that can be directly used by users through production processes such as cutting, straightening, flattening, pressing, hot rolling, cold rolling and stamping.

-

Precision Process on Steel-C Channel with welded parts

Precision Process on Steel and iron is to process all kinds of plates, pipes and wires in the original state of iron and steel into products that can be directly used by users through production processes such as cutting, straightening, flattening, pressing, hot rolling, cold rolling and stamping.

-

Precision Process on Steel-C Channel with welded legs

Concrete Inserts are used in concrete poured walls, floors, ceilings, foundations and pre-cast culverts. Concrete inserts offer a fully-engineered solution, integrating steel channel and parts, to create a cast-in-place concrete framework. This framework provides superior strength and durability to your system.

-

Precision Process on Steel-Bending round pipe short

Precision Process on Steel and iron is to process all kinds of raw steel plates, pipes and wires into products that can be directly used by users by cutting, straightening, flattening, pressing, hot rolling, cold rolling, stamping and other Steel deep processing.

-

Precision Process on Steel-Bending roud pipe

Precision Process on Steel and iron is to process all kinds of plates, pipes and wires in the original state of iron and steel into products that can be directly used by users through production processes such as cutting, straightening, flattening, pressing, hot rolling, cold rolling and stamping.

-

Precision Process on Steel-Bending n’ Punching hole

Steel Structure is one of the materials which used for any kind steel construction, it is formed with a specific shape. These steel materials are of certain standards of chemical composition and proper strength. The steel materials are also defined as hot rolled products, having cross sections like angles, channels and beam. All across the world, there is an increasing demand for steel structures.

The rapid construction is possible in the steel structures. The have good fatigue strength and eused capability of steel construction.

-

Precision Process on Steel-Angle Bar with special welded part

Steel Structure is one of the materials which used for any kind steel construction, it is formed with a specific shape. These steel materials are of certain standards of chemical composition and proper strength. The steel materials are also defined as hot rolled products, having cross sections like angles, channels and beam. All across the world, there is an increasing demand for steel structures.

The rapid construction is possible in the steel structures. The have good fatigue strength and eused capability of steel construction.

-

Precision Process on Steel-Angle Bar with welded parts

Steel Structure is one of the materials which used for any kind steel construction, it is formed with a specific shape. These steel materials are of certain standards of chemical composition and proper strength. The steel materials are also defined as hot rolled products, having cross sections like angles, channels and beam. All across the world, there is an increasing demand for steel structures.

The rapid construction is possible in the steel structures. The have good fatigue strength and eused capability of steel construction.

-

Tailored Welding & Stamping Steel Service/Customized Precision Fabrication

Our company provides welding service for solar tracking system structure, fix solar structure,stamping , cutting service and other tailored welding service. We will manufacutre according to the drawing provided by clients.

-

H beam for Steel structure

Steel Structure is one of the materials which used for any kind steel construction, it is formed with a specific shape. These steel materials are of certain standards of chemical composition and proper strength. The steel materials are also defined as hot rolled products, having cross sections like angles, channels and beam. All across the world, there is an increasing demand for steel structures.

The rapid construction is possible in the steel structures. The have good fatigue strength and eused capability of steel construction.

-

EN BS /356×406 Universal H steel Roof Beams

We work extensively with many of the world’s leading solar tracker and frame manufacturers to help them enrich their size range and reduce logistics costs. By working with us, array system suppliers can optimize their price products and delivery schedules to ensure competitive advantage.

-

Steel H beam

H Beams come in different shapes and sizes. A construction beam is a structural element that bears load by resisting bending from downward forces. Its horizontal span is much broader than its width or depth. Beams are characterized by their profile, length and material.