Featured Products

-

Angle Bar (Lintel) Cross Arm 75*75*8*1700mm

Angle steel is widely used in various metal structures, bridges, machinery manufacturing and shipbuilding, various building structures and engineering structures, such as building beams, bridges, power transmission towers, lifting and transporting machinery, ships, industrial furnaces, reaction towers, container racks, and Warehouse etc.

-

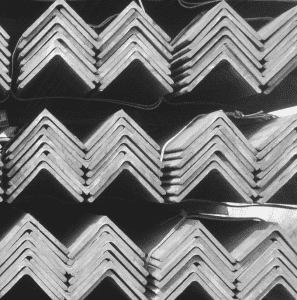

Galvanized Slotted Angle Iron

HDG steel angle are the most basic type of roll-formed steel. They are formed by bending a single angle in a piece of steel. Angle Steel is ‘L’ shaped; the most common type of Steel Angles are at a 90 degree angle. The legs of the “L” can be equal or unequal in length.

-

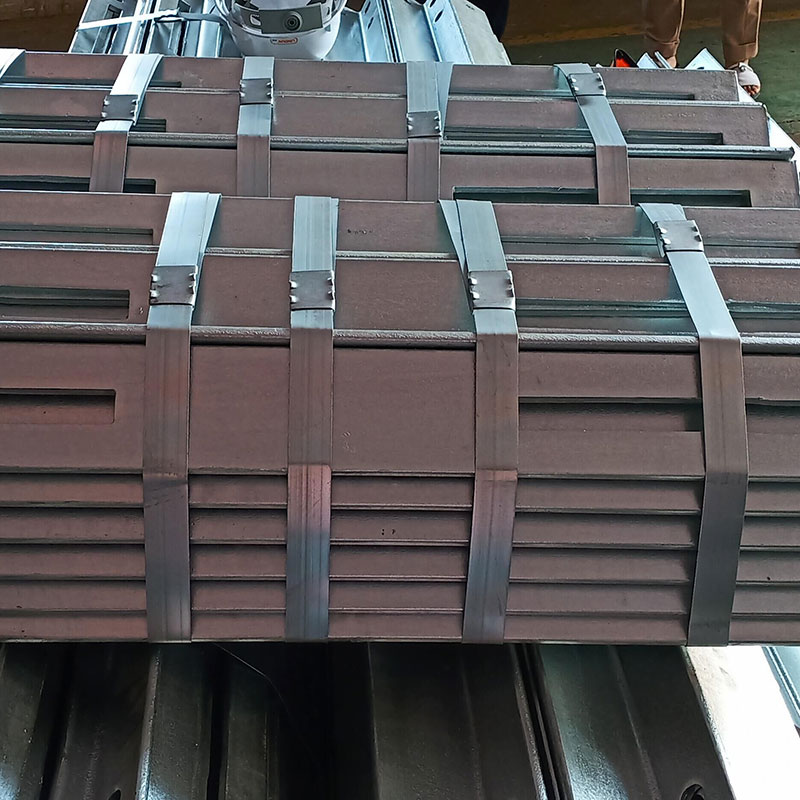

Steel Building Materials Hot Dip Galvanized Steel Ribbed Lintels

Angle Bars protect any corner or surface that needs to keep its shape. It is welded at the structure or attached through drilled fastening. Usually used on a building’s exterior to strengthen the edges. Angle bars reduce erosion and weathering which create significant damages in a structure over time. Heavier loads are better supported by using angle bars.

-

Slotted Metal Angle Bar Angle Bar Metal

Steel Angel is a kind of carbon structural steel for construction. It is a simple section steel. It is mainly used for metal components and the frame of factory buildings. In use, it is required to have better weldability, plastic deformation performance and certain mechanical strength. The raw steel billet for the production of Angle steel is low-carbon square steel billet, and the finished Angle steel is delivered in hot rolled, normalized or hot rolled state.

-

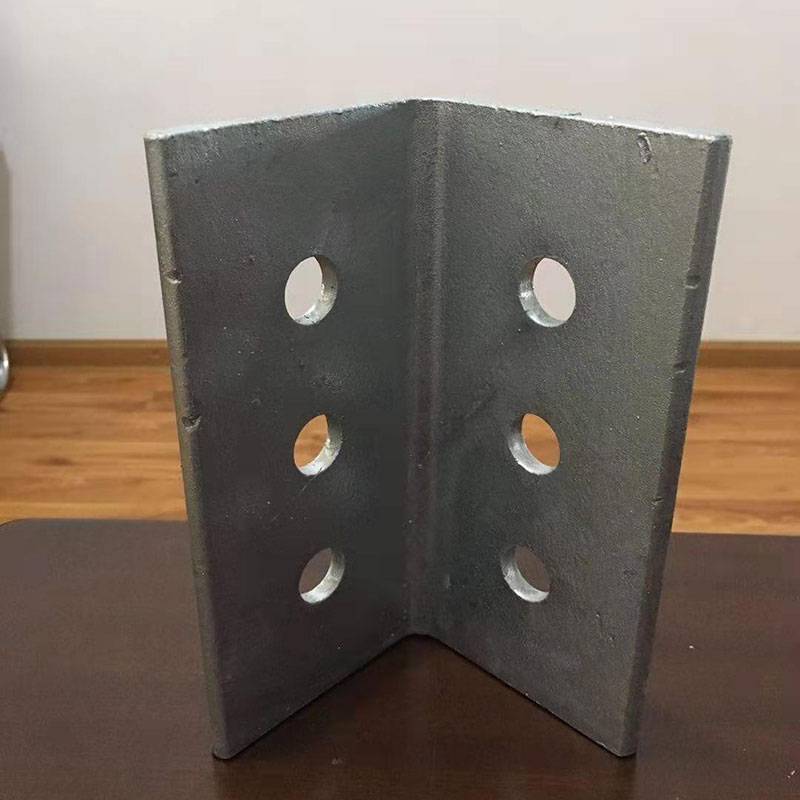

Steel Angle Bar Punching 150*150*10mm

Hot-dip galvanized Steel Angel has the characteristics of surface luster, uniform zinc layer, no leakage, no drip-slip, strong adhesion and strong corrosion resistance. In suburban environment, the standard thickness of hot-dip galvanized rust-proof can be maintained for more than 50 years without repair; in urban or offshore areas, the standard thickness of hot-dip galvanized rust-proof layer can be maintained for 20 years. It doesn’t need to be repaired.

-

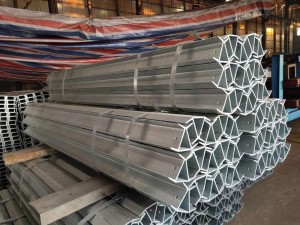

Steel pipe for IBC Container IBC Intermediate bulk container

IBC medium bulk container. Is a modern warehousing, transportation of liquid products, the necessary tools. The container barrel inner container and galvanized steel framework combination, the content of high molecular weight high density polyethylene blow molding, high strength, corrosion resistance, good health

-

Galvanized steel pipe for IBC Tank

IBC medium bulk container. Is a modern warehousing, transportation of liquid products, the necessary tools. The container barrel inner container and galvanized steel framework combination, the content of high molecular weight high density polyethylene blow molding, high strength, corrosion resistance, good health.

-

Galvanized tubing used for Intermediate bulk container steel frame

IBC stands for “Intermediate Bulk Container.” Let’s break that down a bit. Intermediate – IBCs are designed for shipping and storing products and ingredients, they aren’t meant to be a container for the end-user.We mainly produce various parts for ibc.

-

IBC Steel Pallet Base Pan

IBC metal pan /Base pallet /steel plate

-

Continuous Concrete Inserts

Concrete Insert may be used for anchorage on ceilings, floors or walls. Being a pre-pour installation, it is ideal for applications with cracked concrete concerns and avoids the creation of Silica Dust during installation.

-

Sleeper Concrete Retaining Wall Steel Joiner Posts

This presents a stronger, more durable alternative to timber, with a modern range of lightweight concrete sleepers and steel posts.

-Designed for use in retaining walls up to 800mm in height from ground level.

-This system also provides an excellent option for raised garden beds and vegetable patches.

-

Steel Fabrication Galvanized 100UC 14.8 Retaining Wall Post

Galvanised Retaining Wall Post are heavy duty steel available in a fully Hot Dip Galvanized finish for corrosion protection. All posts are pre-drilled to accommodate the unique designed fence brackets.

The Retaining Wall Post system provides an “all in one solution” that accommodates either timber or metal fence connection providing ease of installation & saving time & money. -

Carbon Steel Z Shaped Channel Section Purlin

Steel Sheet Pile are suitable for many temporary and permanent engineering structures. They are characterized by the minimum amount of steel used to provide optimal strength and durability while ensuring their driving performance. The sheet piles are connected to each other through a series of similar joints (locks) that are designed to facilitate connection and piling.

-

Omega Special Shaped Steel Section

cold formed slotted steel section are light framing solution for maximum design flexibility and ease of installation.

-

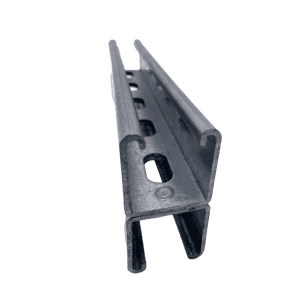

Concrete Insert Strut Channels

Concrete Inserts are used in concrete poured walls, floors, ceilings, foundations and pre-cast culverts. Concrete inserts offer a fully-engineered solution, integrating steel channel and parts, to create a cast-in-place concrete framework. This framework provides superior strength and durability to your system.

-

Precision Process on Steel- Solar Mounting system parts

Deep processing of iron and steel is to process all kinds of raw steel plates, pipes and wires into products that can be directly used by users by cutting, straightening, flattening, pressing, hot rolling, cold rolling, stamping and other production processes.

-

Precision Process on Steel- Special parts

Deep processing of iron and steel is to process all kinds of raw steel plates, pipes and wires into products that can be directly used by users by cutting, straightening, flattening, pressing, hot rolling, cold rolling, stamping and other production processes.

-

Precision Process on Steel- Special plate

Deep processing of iron and steel is to process all kinds of raw steel plates, pipes and wires into products that can be directly used by users by cutting, straightening, flattening, pressing, hot rolling, cold rolling, stamping and other production processes.

-

-

Precision Process on Steel-Welding and hole on Angle bar

Deep processing of iron and steel is to process all kinds of raw steel plates, pipes and wires into products that can be directly used by users by cutting, straightening, flattening, pressing, hot rolling, cold rolling, stamping and other production processes.

-

Cold Formed Welding H B 2 B profile

strut channel & slotted strut channel