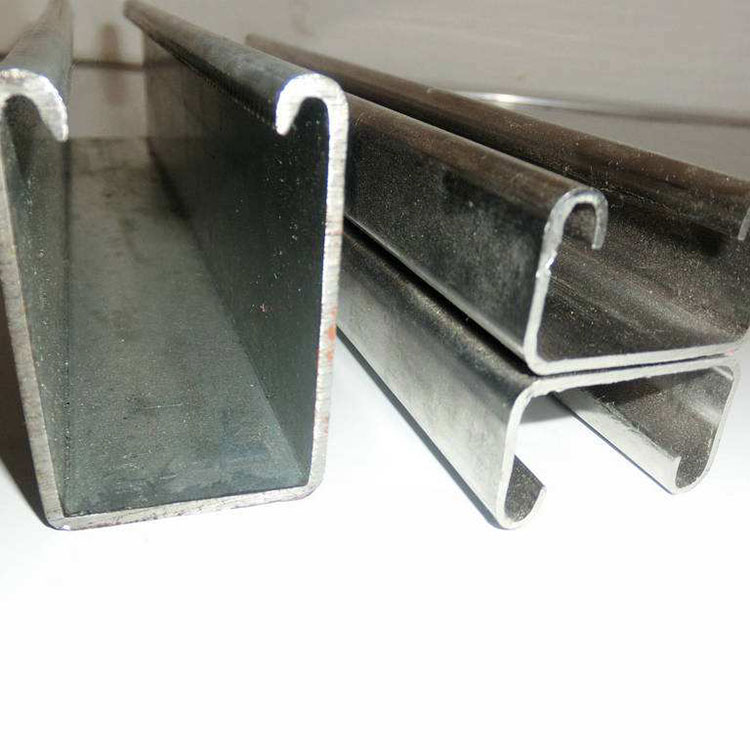

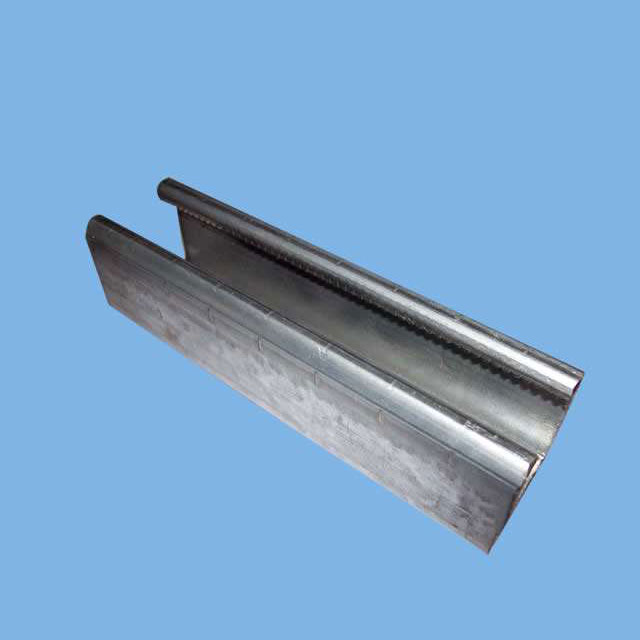

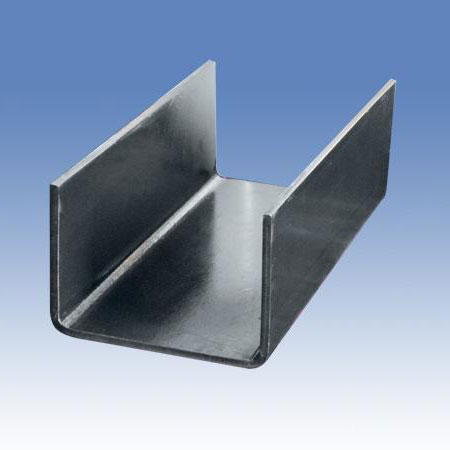

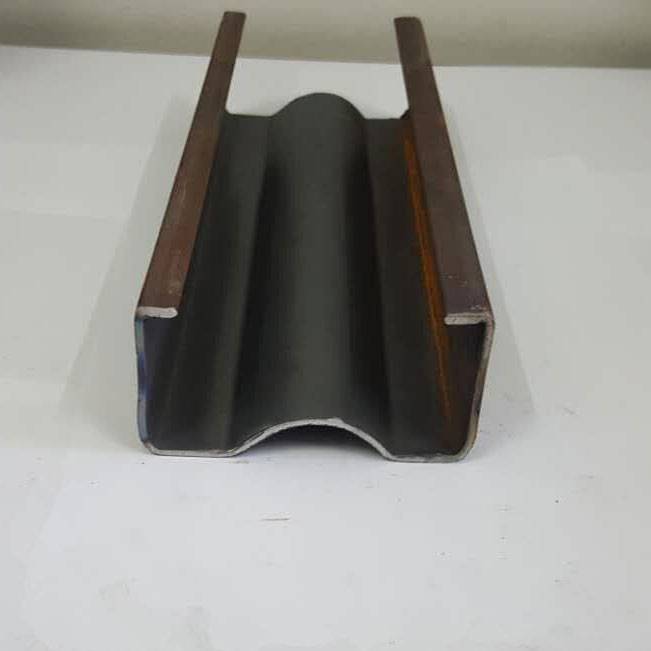

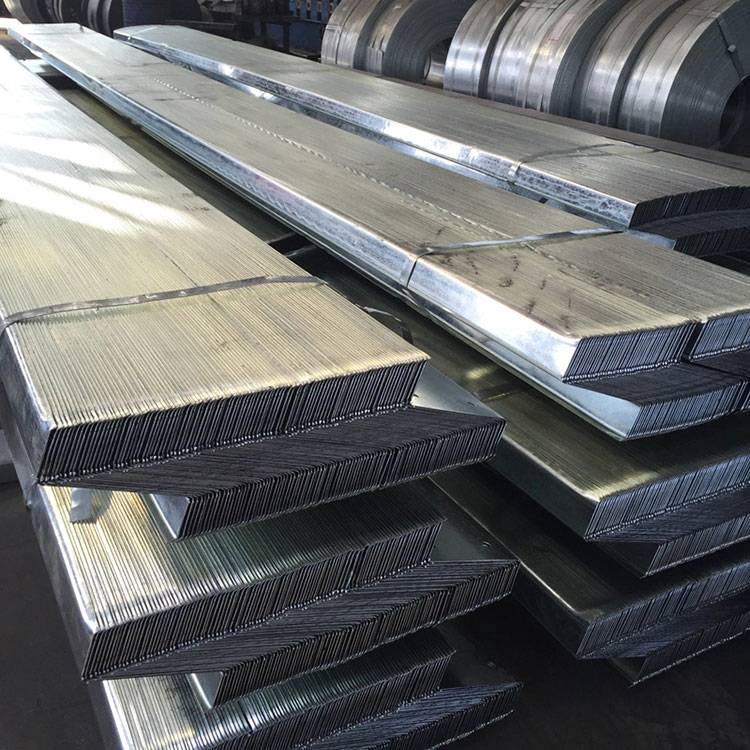

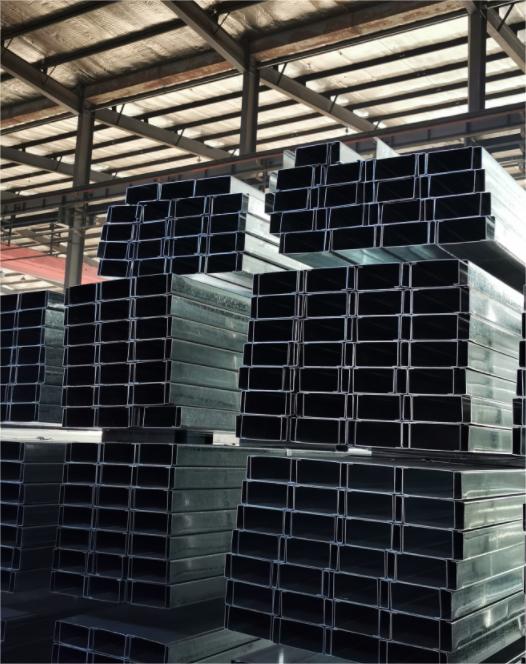

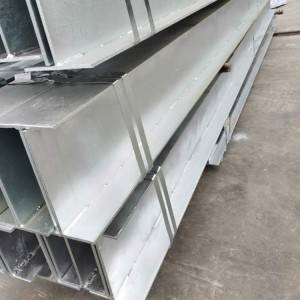

formed C-section Steel

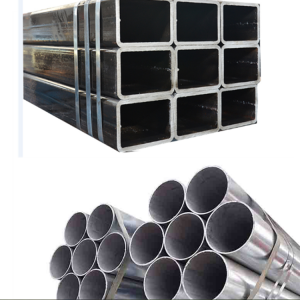

Cold Formed Section Steel refers to finished steel with various sectional forms bent by steel plates or strip steels under cold states. It is a kind of economic light-weight thin-wall sectional steel,also named as cold-forming steel or cold-formed steel. It is main material of making light steel structures.It features all kinds of extra-thin,reasonable-shape and complex sections which hot rolling cannot produce.Compared to hot rolled section steel,under situation with the same section area, its turning radius can add 50-60% and second moment of area can increase by 0.5-3.0 times, which therefore, is capable of using material strength reasonably;compared to normal steel structures (that made of joist steel,U-steel,angle steel,and steel plate),it can save about 30-50% of steels.

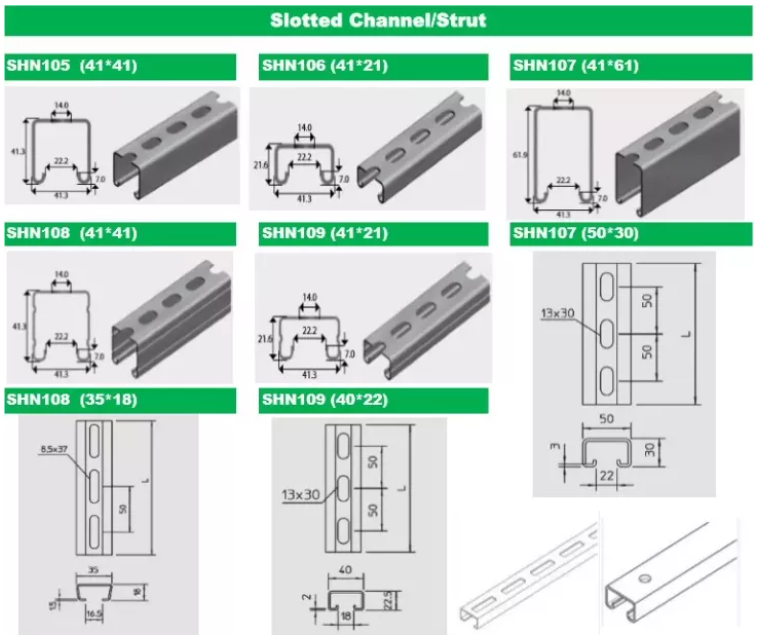

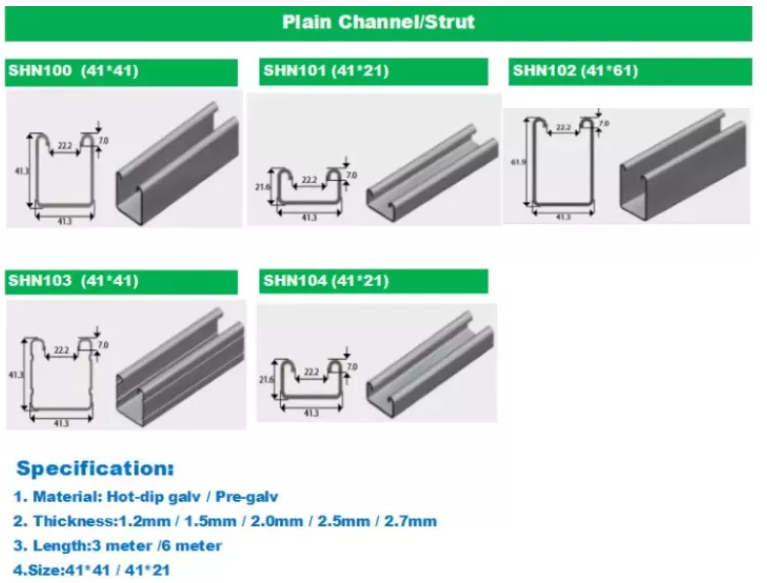

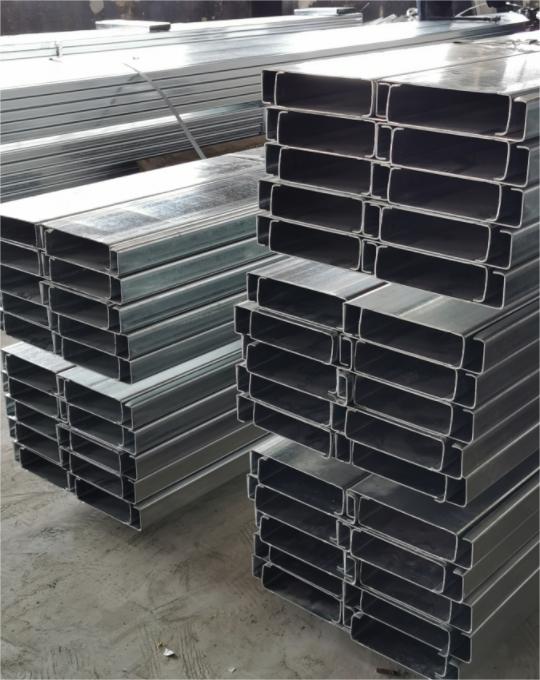

Steel C Channel Introduction

1)Definition:Steel C Channel is processed automatically by C-steel make-up machine, which, according to given C-steel sizes, can automatically complete the C- steel forming process.

2)Material:Q195,Q235,Q345

3)Surface Treatment:Galvanized,?Paint,?Black mild channel bar.

4)Packing:In bundle, as customer specific requirements

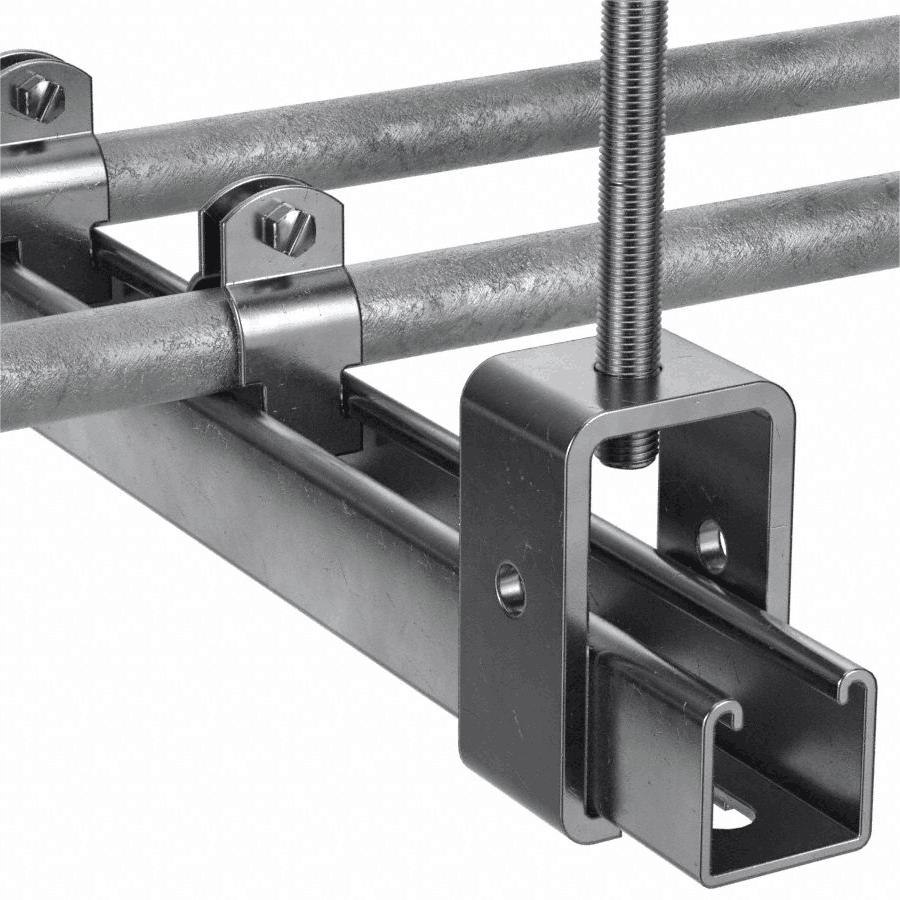

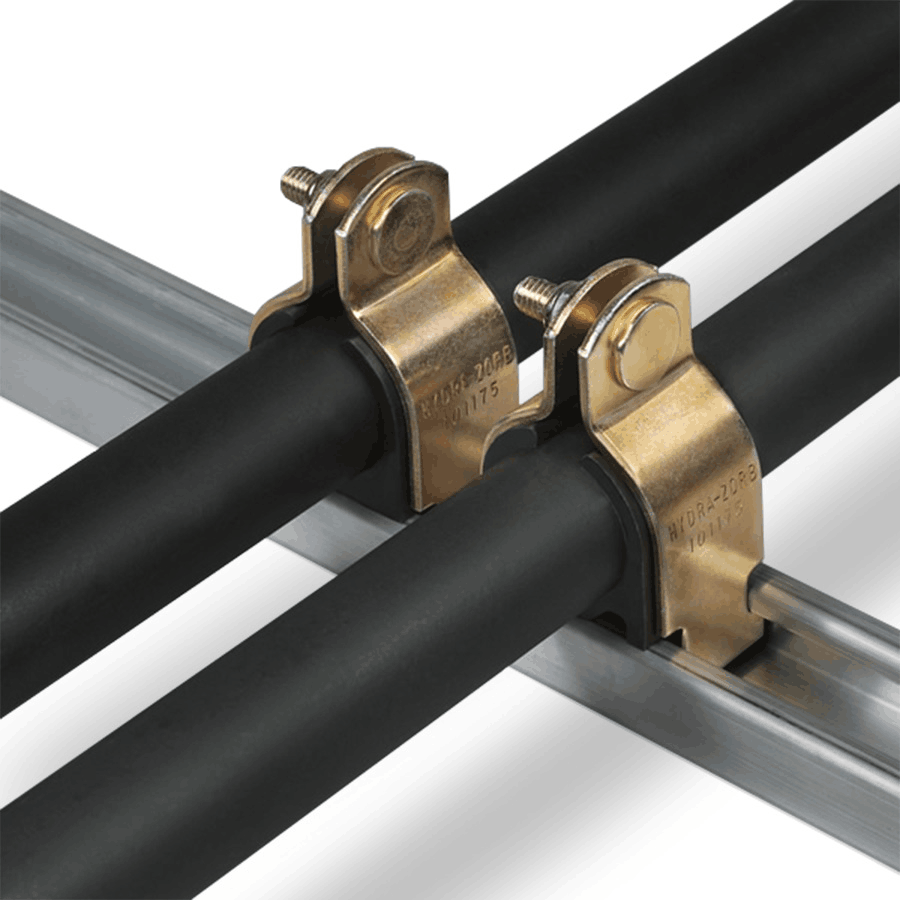

(1)Strip mounting holes on the back, easy to adjust and install can be customized according to customer requirements

(2)Can be arbitrarily matched with all professional accessories for safe use

(3)Standard length of 6 meters, can be customized according to customer requirements.

(4) Hot-dip galvanized surface treatment the thickness of the galvanized layer is more than65UM, and the appearance is simple and beautiful.

According to different project topography and meteorological environment, we provide customer with solutions such as double pole solar solution, single poles solar solution, screw pile solar solution, combination of steel pole and embedded concrete, single pole of fishing complementary solution and PV agricultural greenhouse solution.