High Quality Solar Panel Mounting Bracket - Fixed Solar Mounting System – Rainbow

High Quality Solar Panel Mounting Bracket - Fixed Solar Mounting System – Rainbow Detail:

According to different project topography and meteorological environment, we provide customer with solutions such as double pole solar solution, single poles solar solution, screw pile solar solution, combination of steel pole and embedded concrete, single pole of fishing complementary solution and PV agricultural greenhouse solution.

We provide customer with all the steel material for solar fixed mounting system, including front and rare columns, main pillars,beams, inclined beams, purlins.

The material mainly used for fixed solar system are:

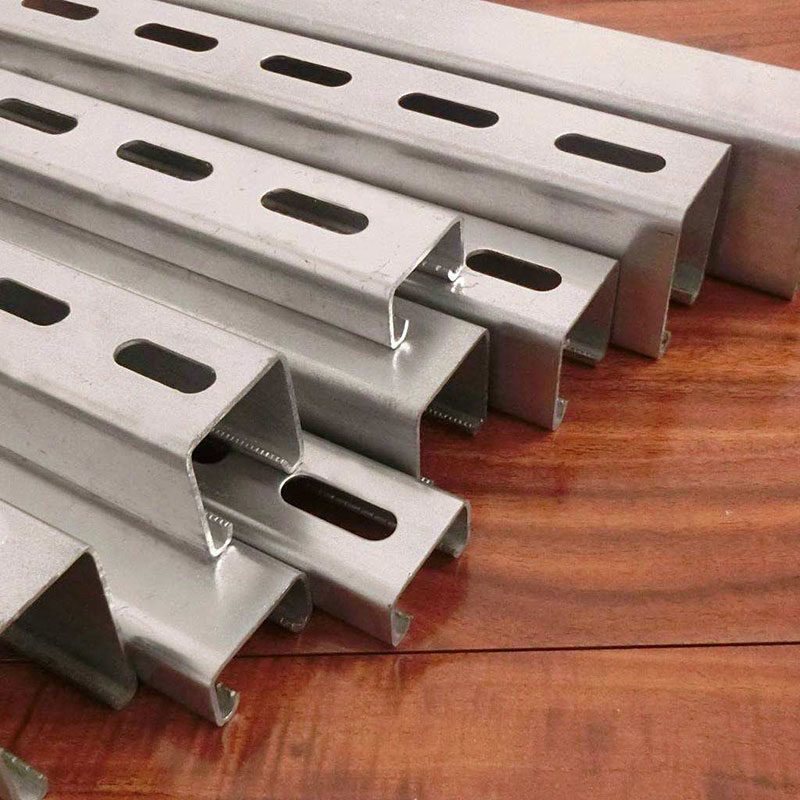

1.Steel C/U channel:

Item: Hot dip galvanized Cold Formed C/U Profile Ground Piles

Material: Q355,S355

Standard: GB/T1591

Surface: Hot dip galvanized according to ASTM A123, BS4687, GB/T13912

Specification: C80*80*15*3.0, C100*100*20*3.5, U150*80*4.0, U160*80*4.5

C Channel

U channel

|

U Specification (mm) |

Width (mm) |

Height (mm) |

Thickness (mm) |

Theoretical Weight (kg/m) |

| 80*40 | 80 | 40 | 3 | 3.511 |

| 80*40 | 80 | 40 | 4 | 4.568 |

| 100*50 | 100 | 50 | 3 | 4.453 |

| 100*50 | 100 | 50 | 4 | 5.824 |

| 120*60 | 120 | 60 | 3 | 5.395 |

| 120*60 | 120 | 60 | 4 | 7.08 |

| 120*60 | 120 | 60 | 5 | 8.64 |

| 140*60 | 140 | 60 | 3 | 5.866 |

| 140*60 | 140 | 60 | 4 | 7.708 |

| 140*60 | 140 | 60 | 5 | 9.425 |

| 160*80 | 160 | 80 | 4 | 9.592 |

| 160*80 | 160 | 80 | 5 | 11.78 |

| 160*80 | 160 | 80 | 6 | 13.95 |

| 180*80 | 180 | 80 | 4 | 10.22 |

| 180*80 | 180 | 80 | 5 | 12.565 |

| 180*80 | 180 | 80 | 6 | 14.891 |

| 200*80 | 200 | 80 | 4 | 10.848 |

| 200*80 | 200 | 80 | 5 | 13.35 |

| 200*80 | 200 | 80 | 6 | 15.833 |

2. Steel H beams:

The material is made of American standard wide-flange H-beam with the size standard of ASTM A6. The steel grade can be selected between ASTM A572 GR50 /GR60, ASTM A992 or Q355. The hot-dip galvanizing meets ASTM A123, ISO1461 and AS/NZS4680 standards.

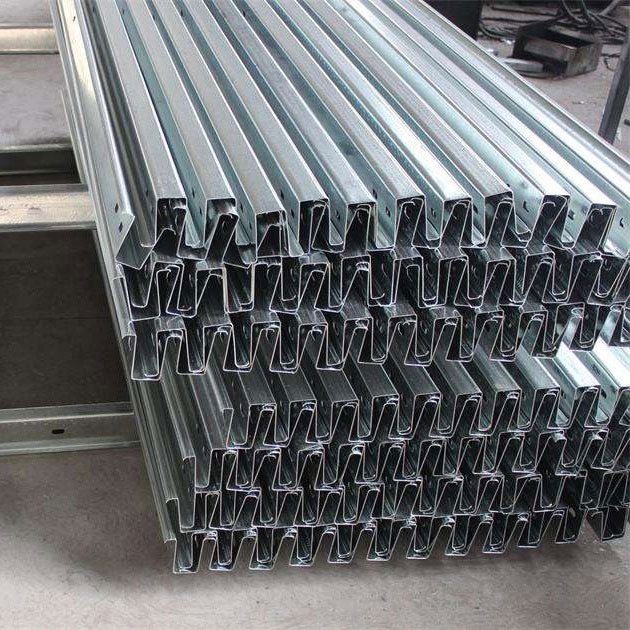

3. Special U-steel:

1.Products Introduction

1)Material: Q195,Q235,Q345,SS400,A36 or ST37-2

2)Surface Treatment: Galvanized, Paint, Black mild channel bar.

3)Packing: In bundle, as customer specific requirements, suitable for long distance ocean transportation.

4)Application: solar power station, construction etc.

5)Customization: can be customized according to customers’drawings, and galvanization can be adjusted according to requirements.

6)Main features: big stress resistance, long support time, easy installation and low deformation.

Special U-steel has cross section shaping like letter of the Greek alphabet omega (Ω) , which wildly used in the filed of photovoltaic solar mounting system : for the purlins, beams or bracing parts of solar brackets.

Product detail pictures:

Related Product Guide:

Greenhouse commonly used steel greenhouse introduction

Technical Specification for safety of steel pipe scaffold for construction

We're commitment to offer you the aggressive cost ,superb products and solutions top quality, too as fast delivery for High Quality Solar Panel Mounting Bracket - Fixed Solar Mounting System – Rainbow , The product will supply to all over the world, such as: Swaziland, Chile, Yemen, Our company is working by the operation principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a friendly relationship with businessman from all over the world.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!