Longitudinal Seam Submerged Arc Welded Steel Pipe - Precision Process on Steel-Galvanized U Attachment for Gound mounting – Rainbow

Longitudinal Seam Submerged Arc Welded Steel Pipe - Precision Process on Steel-Galvanized U Attachment for Gound mounting – Rainbow Detail:

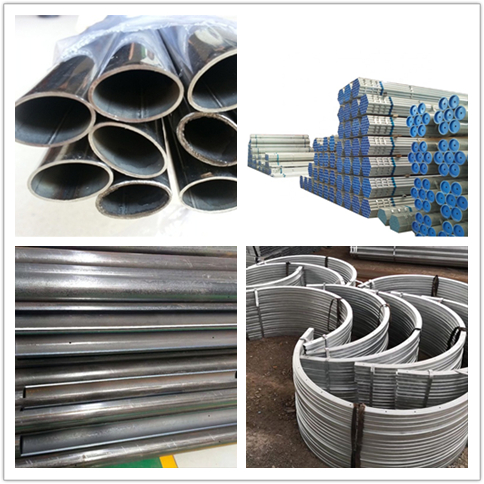

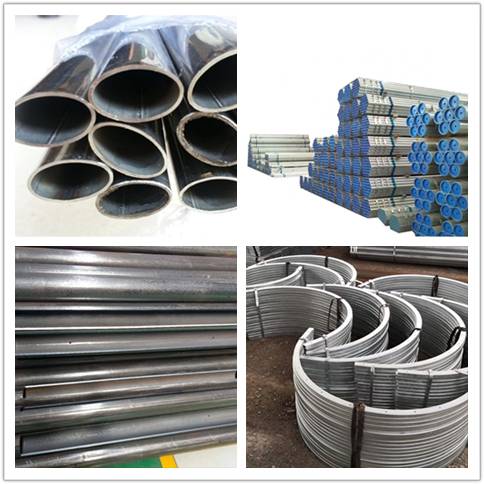

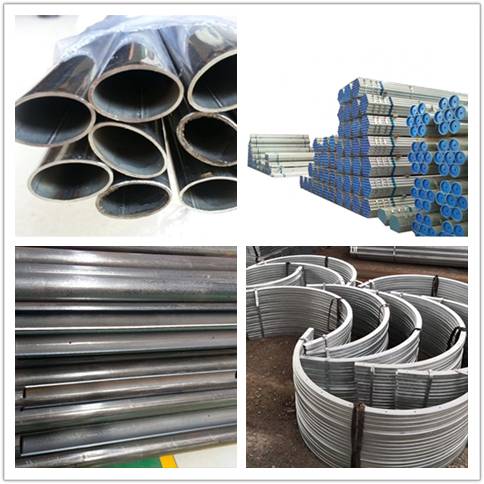

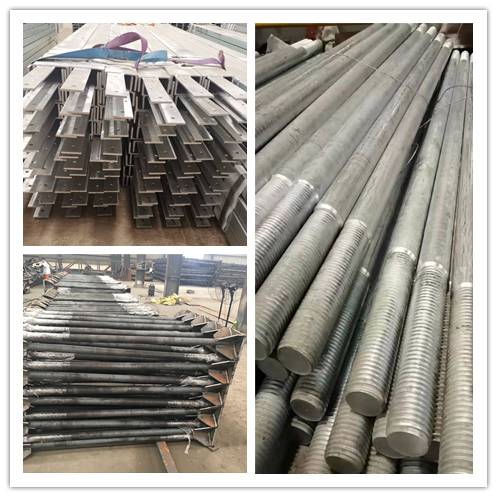

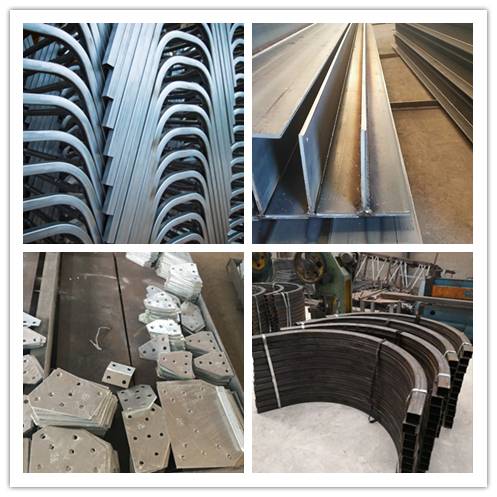

Deep processing of iron and steel is to process all kinds of raw steel plates, pipes and wires into products that can be directly used by users by cutting, straightening, flattening, pressing, hot rolling, cold rolling, stamping and other production processes.

We can do kinds of precision process on steel.

- Beveled End

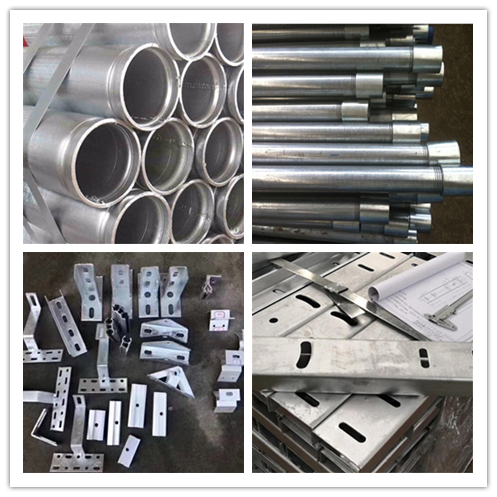

- Steel Cap

- Swage n’ Hole

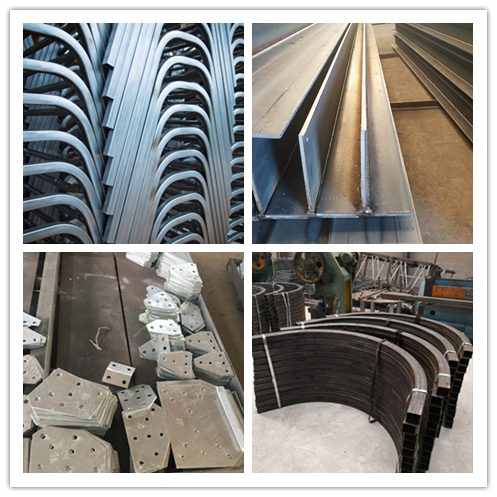

- Bending n’ Punching hole

- Making Groove

- Threading n’ Coupling

- Welded Part for Solar Mounting System

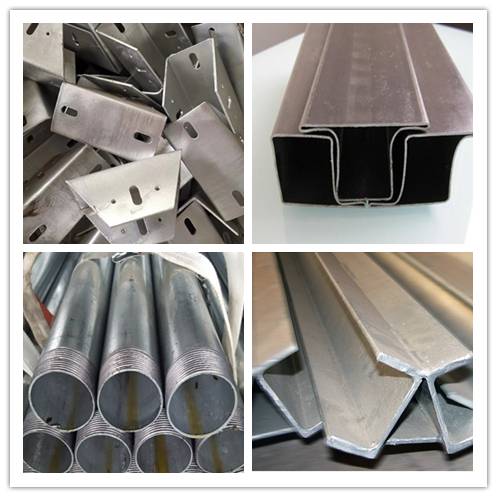

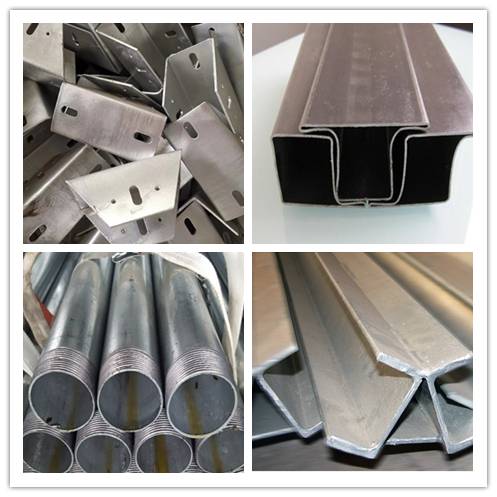

- Galvanized U Attachment for Ground Mounting

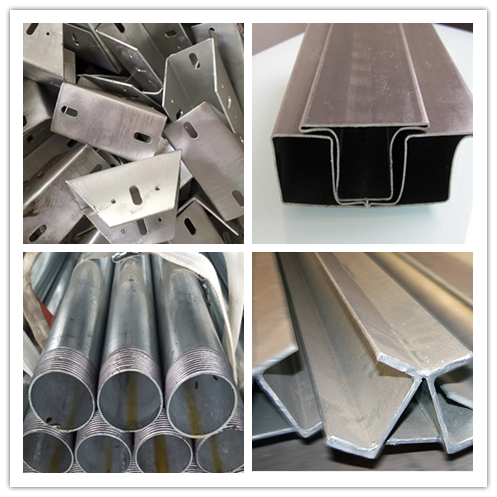

- Steel Pipe Flattening & Holing

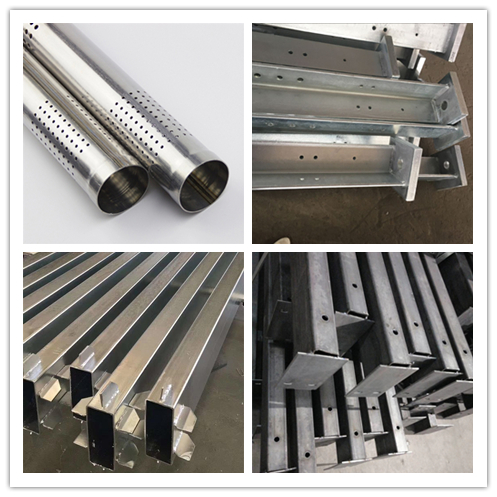

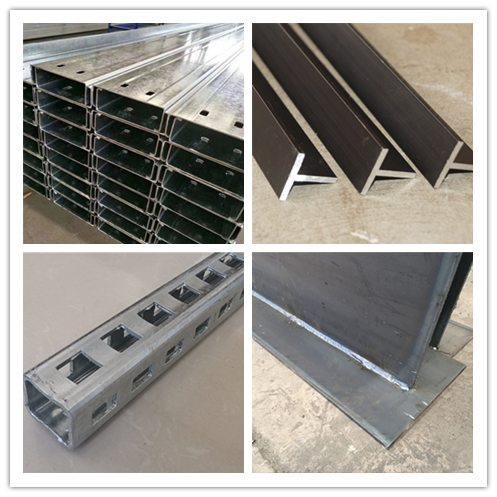

- C Channel with Welded Part

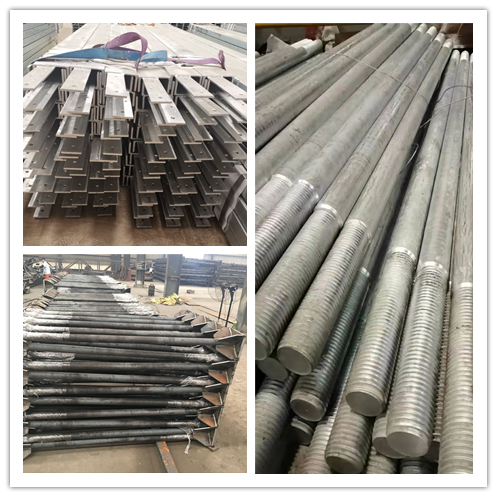

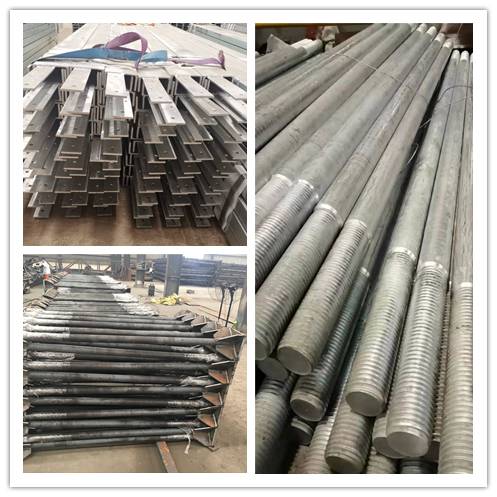

- Galvanized Anchor Bolt From Steel Round Bar

- Anchor Bolt by Pipe Welded Plate

- Holing on steel pipe

- Steel Angle Bar with Punched Hole and Welding Plate

- Welding on Steel Pipe

- I beam with Punched Holes

- Cold Formed Galvanized Beam

- Galvanized Steel T Bar or T Lintels

- Changed from Round Pipe, Then Laser Holing

- Submerged ARC Welding

- Welded C Channel

- Iron Angle Holing & Cutting

- Plasma NC Cutting Steel Plate

- C Channel with Welded Legs

Product detail pictures:

Related Product Guide:

Technical Specification for safety of steel pipe scaffold for construction

Some problems in the construction of steel structure and their solutions

Our growth depends on the superior equipment ,exceptional talents and continuously strengthened technology forces for Longitudinal Seam Submerged Arc Welded Steel Pipe - Precision Process on Steel-Galvanized U Attachment for Gound mounting – Rainbow , The product will supply to all over the world, such as: Angola, Florence, Lebanon, we're now looking forward to even greater cooperation with overseas customers based on mutual benefits. We are going to work wholeheartedly to improve our products and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!

Write your message here and send it to us