Manufacturer for Galvanized Steel Electric Tower - Power Transmission Pole – Rainbow

Manufacturer for Galvanized Steel Electric Tower - Power Transmission Pole – Rainbow Detail:

1. Steel Tube Pole

Part I (Brief) :

Electric steel pole is a new set up power lines of power equipment in recent years, who are instead of traditional cement column wire rod products.Electric steel pole can be manufactured of polygonal and round steel pipe,and processed by hot dip galvanized. Mainly used for power line erection.

Part II (Characters and advantages):

1. Small area covered. 2. Smart appearance. 3. Convenient construction. 4. Short production.

Part III (Specifications):

| Height | 25FT~70FT |

| Suit for | Electric Power Transmission and Distribution/ Steel Tower Pole |

| Shape | Polygonal |

| Material | Normally :Q235B/ASTMA36/ENS235JR,Yeild Strength≥235MPa;Q345B/ASTMA572/ENS355J2, Yeild Strength≥345MPa |

| Power Capacity | 10kV to 220kV |

| Tolerance of the dimension | According to client’s requirement |

| Surface treatment | Hot-dip-galvanized following ASTM123, or any other standard by client’s requirement |

| Joint of Poles | Slip joint, flanged connected |

| Standard | ISO9001:2008 |

| Length of per section | Within 14M once forming |

| Welding Standard | AWS(American Welding Society)D 1.1 |

| Thickness | 2~30mm |

| Production Process | Raw material test-cutting-bending-welding-dimension verify-flange welding-hole drilling-sample assemble-surface clean-galvanization or power coating /painting-recalibration-packages |

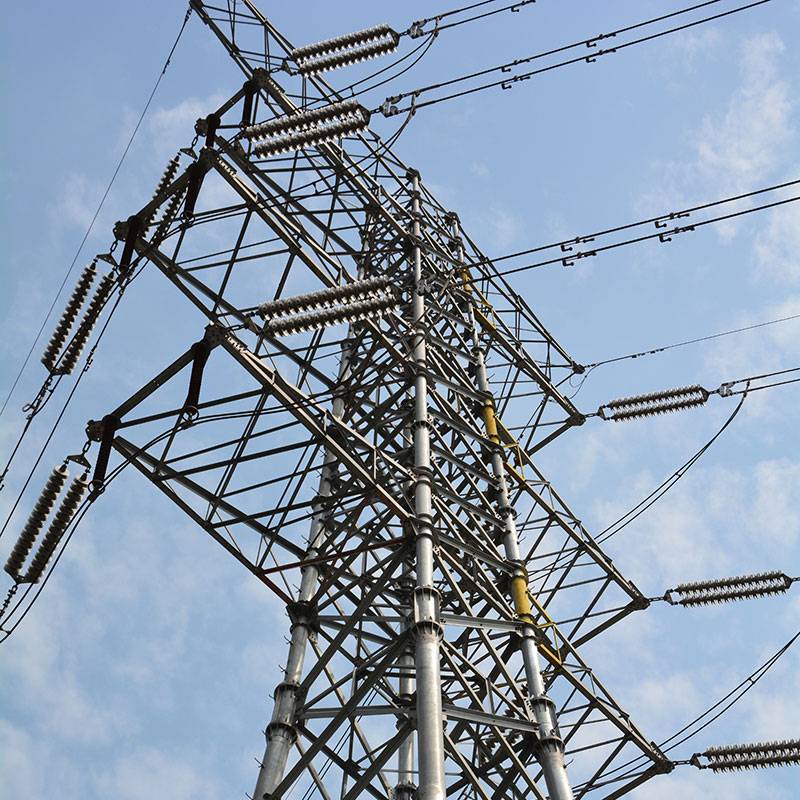

2. Angel Steel Tower

Model Number: 220kV and below

Material: Steel Q235B Q345B Q420

Out Coating: Hot Dip Galvanized

Color: Silver/White

Application: 220kV and blow

Quality Control: ISO9001:2008

Welding Standard: AWS D 1.1

Galvanization Standard: ASTM123

Warranty Period: 20 years

Angle steel tower is a downcomer tray column.The plate pressure drop is small, with a large amount of gas, the plate efficiency is good, has the advantages of simple structure, convenient manufacture, good rigidity.

Part one (Characters and advantages) :

1. Transmission steel tower has single circuit line and double circuit line.

2. It is mainly composed of equilateral angle steel, and material used by Q235(A3F) or Q345(16Mn).

3. Steel tower is mainly composed of three parts: head tower, body tower and leg tower.

4. Steel Tower always used by transmission power line and EHV.

Part Two(Specifications):

| Material | Normally Q235B/A36,Yeild Strength≥235MPaQ345B/A572,Yeild Strength≥345MPa |

| Power Capacity | 10kV ,13.8kV,69kV,110kV,132kV,220kV or other |

| Tolerance of the dimension | According to client’s requirement |

| Surface treatment | Hot-dip-galvanized following ASTM123, or any other standard by client’s requirement |

| Standard | ISO9001:2008 |

| Production Process | Raw material test-Angle Marking -Hole Drilling-Angle Cutting-Angle Shovelling- Angle Fring –Angle Welding-Sample Assemble-Surface Clean-Galvanization -Recalibration-Packages |

| Packages | packing by bundles(set-wise or member-wise)with weight of 2~3 tons or according to client’s requirement |

3. High Lamp-post

| Product name | galvanized solar street lighting poles / street lamp post |

| Material | Q235,Q345,iron,Steel |

| Color | Customized |

| Height | 3-35 m |

| Thickness | 1.8mm-14mm |

| Surface treatment | Hot-Dip Galvanized and electrostatic spraying |

| Shape | Conical,octagonal,Customized |

| Arm type | Customized,single arm,double arms,triple arms |

| Base plate mounted | anchor bolts,nuts,screws |

| Powder coating | electrostatic spraying |

| Wind Resistance | Customized,according to customers’ environment |

| Welding standard | Advanced submerge-arc welding technology according to BS EN15614 |

| Thickness of galvanized | 80-100 microns in average according to BS EN ISO 1461 |

Product detail pictures:

Related Product Guide:

Some problems in the construction of steel structure and their solutions

Fire protection measures for steel structures

Our focus on should be to consolidate and enhance the quality and repair of present products, in the meantime constantly establish new products to meet unique customers' requires for Manufacturer for Galvanized Steel Electric Tower - Power Transmission Pole – Rainbow , The product will supply to all over the world, such as: Philippines, Grenada, Bulgaria, Many years of work experience, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!