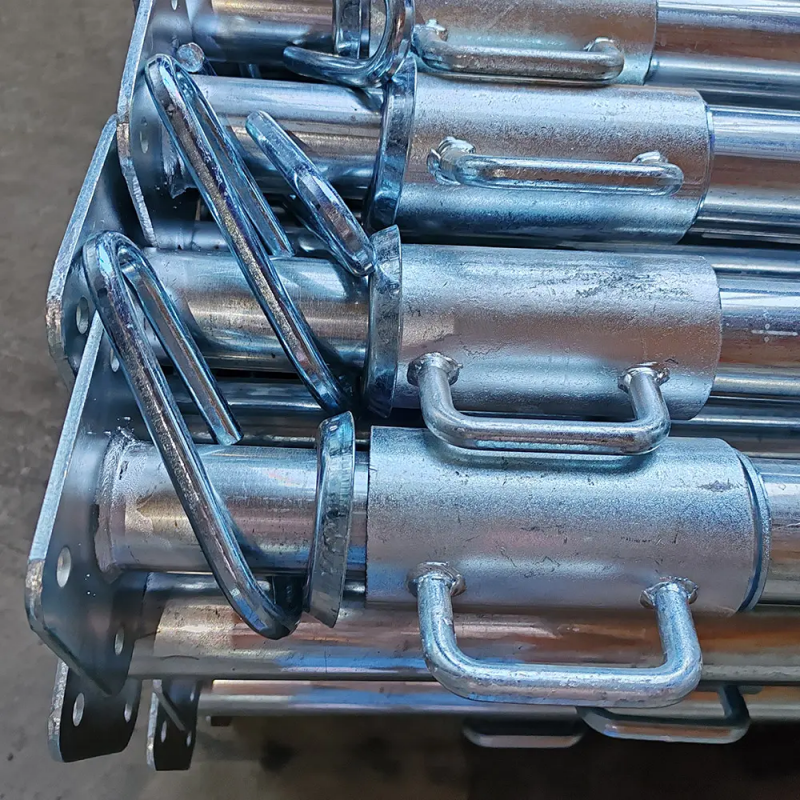

Adjustable Steel Prop Accessories Scaffolding Cup Nut

Heavy Duty Adjustable Scaffolding Steel Formwork Construction Jack

(1)Steel prop is mainly made of bottom plate, outer tube, inner tube, swivel nut,cotter pin, upper plate and the accessories of folding treipod, head jack, the structure is simple and flexible.

(2)The structure of steel prop is simple, so it is easy to assemble and disassemble.

(3)Steel prop is adjustable because the inner tube can extend and shrink in the outer tube, so it can be adjusted according to the required height.

(4) The steel prop can be reused. Even though it is out of work, the material can also be recycled.

(5)Steel prop can be adjusted according to the different height of the cnstructions.

|

Specification

|

Steel Prop

|

|

Outer Diameter

|

48mm--60mm; 40mm--48mm;

|

|

Pope Thickness

|

1.5mm--3mm

|

|

Length

|

600mm--5000mm

|

|

Standard

|

GB, ANSI, ASME, ASTM, JIS, DIN, BS, EN

|

|

Material

|

Q195,Q235, Q345

|

|

Package

|

in pallets or in bundle or in bulk

|

|

Surface Treatment

|

dipping painted

|

|

Type

|

heavy duty or light duty

|

|

Application

|

slab or formwork supporting

|

|

Weight

|

4.74kg--30kg

|

Write your message here and send it to us