Seam Submerged Steel Pipe - Precision Process on Steel-Welding parts and holing – Rainbow

Seam Submerged Steel Pipe - Precision Process on Steel-Welding parts and holing – Rainbow Detail:

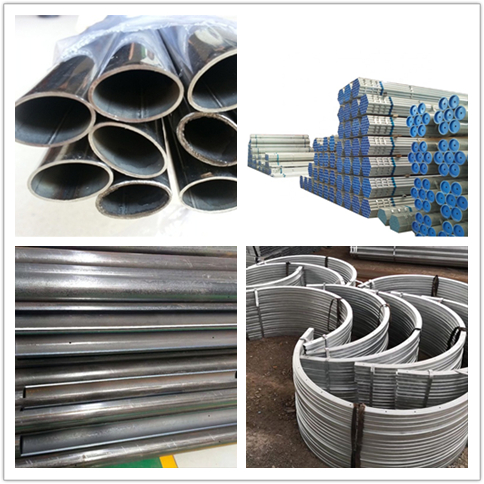

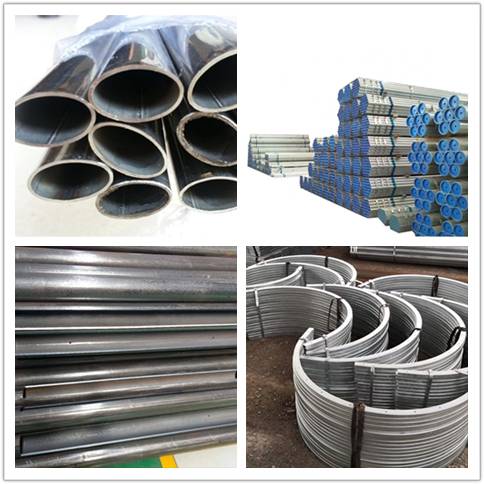

Deep processing of iron and steel is to process all kinds of raw steel plates, pipes and wires into products that can be directly used by users by cutting, straightening, flattening, pressing, hot rolling, cold rolling, stamping and other production processes.

We can do kinds of precision process on steel.

- Beveled End

- Steel Cap

- Swage n’ Hole

- Bending n’ Punching hole

- Making Groove

- Threading n’ Coupling

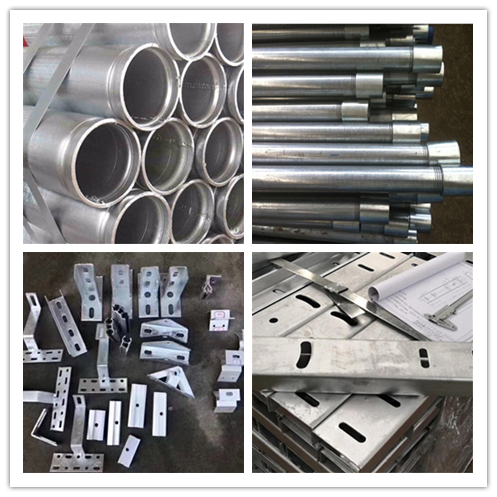

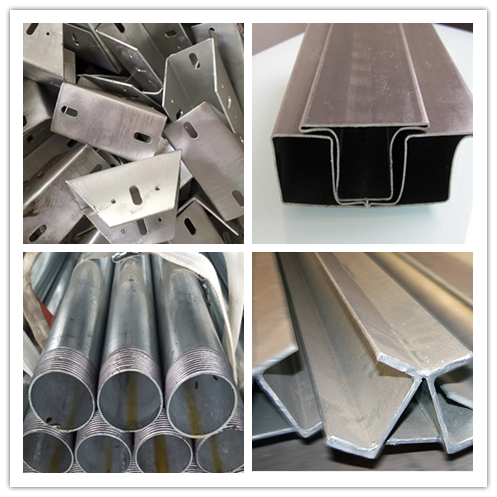

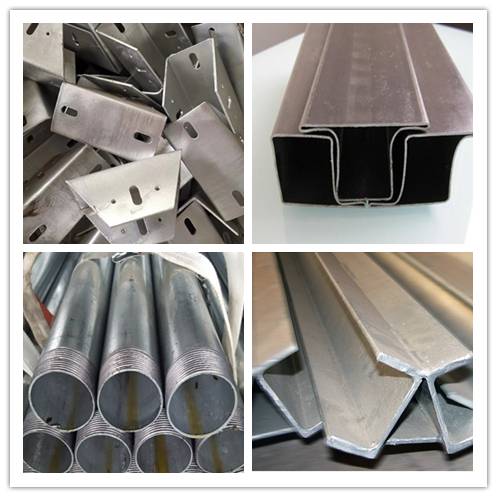

- Welded Part for Solar Mounting System

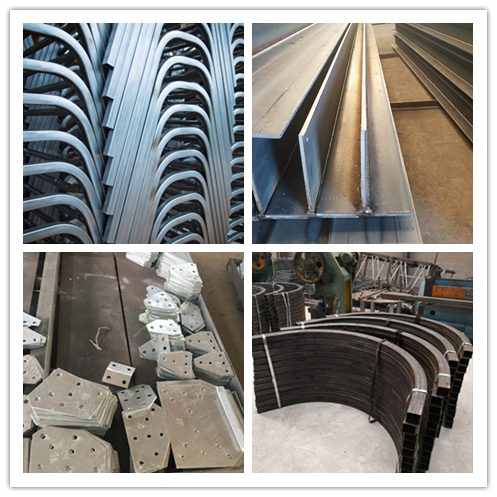

- Galvanized U Attachment for Ground Mounting

- Steel Pipe Flattening & Holing

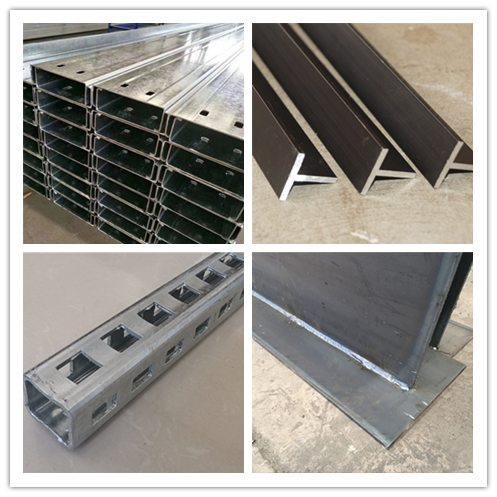

- C Channel with Welded Part

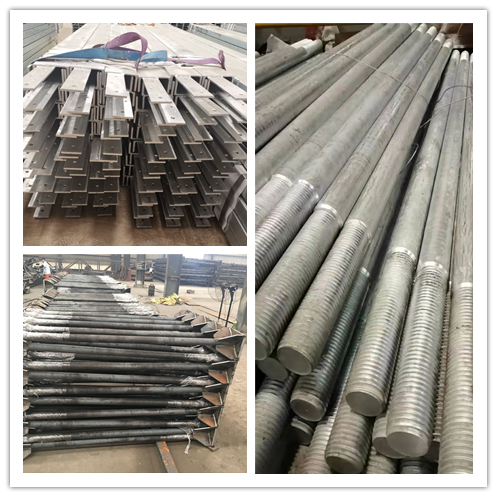

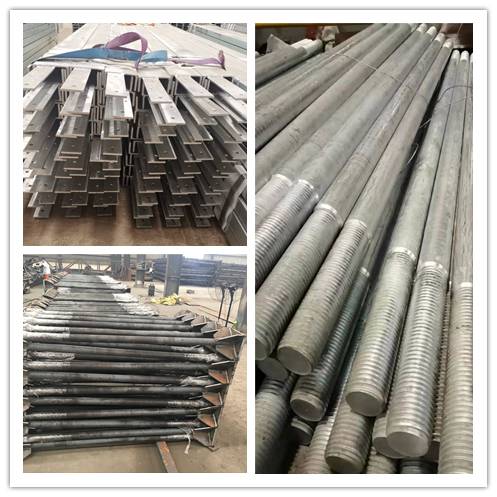

- Galvanized Anchor Bolt From Steel Round Bar

- Anchor Bolt by Pipe Welded Plate

- Holing on steel pipe

- Steel Angle Bar with Punched Hole and Welding Plate

- Welding on Steel Pipe

- I beam with Punched Holes

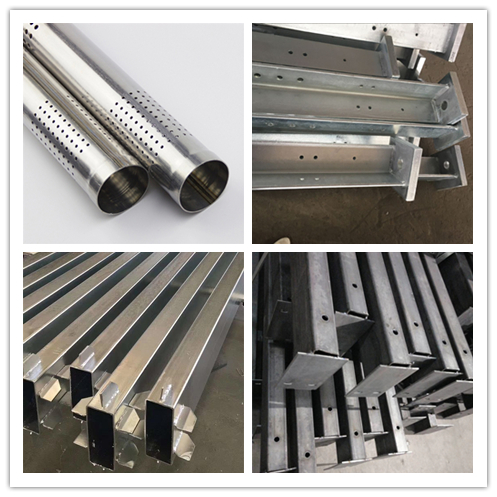

- Cold Formed Galvanized Beam

- Galvanized Steel T Bar or T Lintels

- Changed from Round Pipe, Then Laser Holing

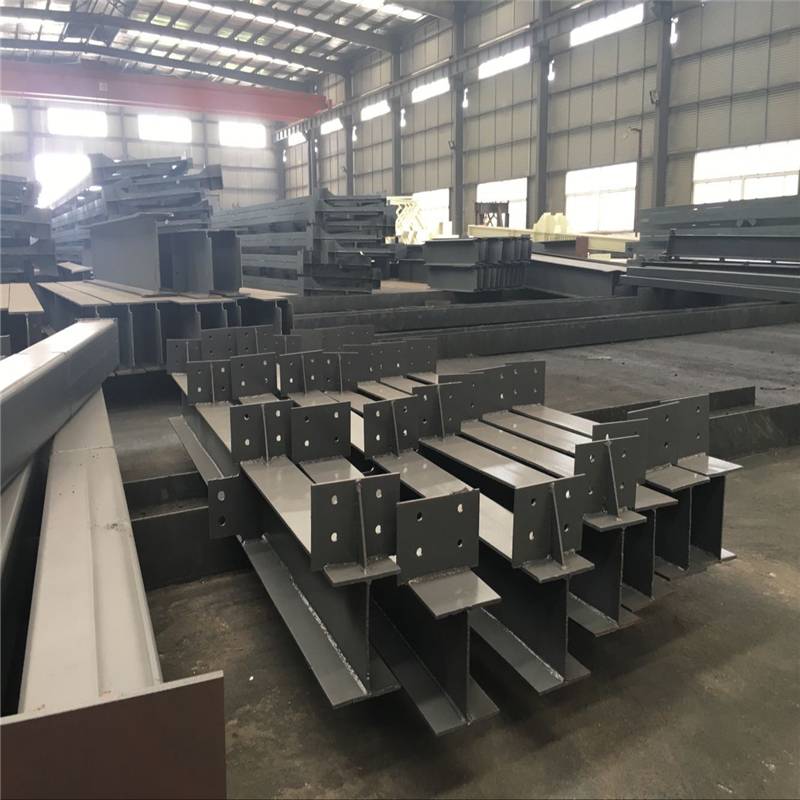

- Submerged ARC Welding

- Welded C Channel

- Iron Angle Holing & Cutting

- Plasma NC Cutting Steel Plate

- C Channel with Welded Legs

Product detail pictures:

Related Product Guide:

Fire protection measures for steel structures

4 kinds of methods of steel structure interlayer

We now have a skilled, performance team to supply good quality services for our consumer. We often follow the tenet of customer-oriented, details-focused for Seam Submerged Steel Pipe - Precision Process on Steel-Welding parts and holing – Rainbow , The product will supply to all over the world, such as: Plymouth, Washington, Costa rica, Our products are mainly exported to Southeast Asia, the Middle East, North America and Europe. Our quality is surely guaranteed. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.

Write your message here and send it to us