Slotted Angle Bar - Slotted Metal Angle Bar Angle Bar Metal – Rainbow

Slotted Angle Bar - Slotted Metal Angle Bar Angle Bar Metal – Rainbow Detail:

Product Description:

Steel Angel can be composed of different stress components according to the different needs of the structure, and can also be used as a connecting part between components. Widely used in a variety of building structures and engineering structures, such as beams, Bridges, transmission towers, lifting and transportation machinery, ships, industrial furnaces, reaction towers, container frames, cable trench support, power piping, bus support installation, and warehouse shelves.

Steel Angel is a kind of carbon structural steel for construction. It is a simple section steel. It is mainly used for metal components and the frame of factory buildings. In use, it is required to have better weldability, plastic deformation performance and certain mechanical strength. The raw steel billet for the production of Angle steel is low-carbon square steel billet, and the finished Angle steel is delivered in hot rolled, normalized or hot rolled state.

Product Specification:

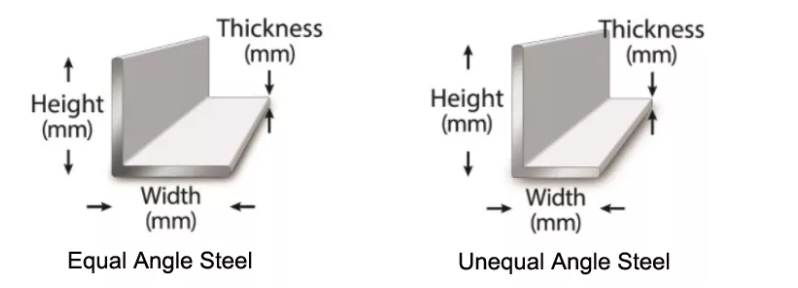

| Equal Angle Bar | |||||

| Size(mm) | Theoretical Weight (kg/m) |

Size(mm) | Theoretical Weight (kg/m) |

Size(mm) | Theoretical Weight (kg/m) |

| 25*3 | 1.124 | 70*6 | 6.406 | 100*16 | 23.257 |

| 25*4 | 1.459 | 70*7 | 7.398 | 110*8 | 13.532 |

| 30*3 | 1.373 | 70*8 | 8.373 | 110*10 | 16.69 |

| 30*4 | 1.786 | 75*5 | 5.818 | 110*12 | 19.782 |

| 40*3 | 1.852 | 75*6 | 6.905 | 110*14 | 22.809 |

| 40*4 | 2.422 | 75*7 | 7.976 | 125*8 | 15.504 |

| 40*5 | 2.967 | 75*8 | 9.03 | 125*10 | 19.133 |

| 50*3 | 2.332 | 75*10 | 11.089 | 125*12 | 22.696 |

| 50*4 | 3.059 | 80*6 | 7.736 | 125*14 | 26.193 |

| 50*5 | 3.77 | 80*8 | 9.658 | 140*10 | 21.488 |

| 50*6 | 4.465 | 80*10 | 11.874 | 140*12 | 25.522 |

| 60*5 | 4.57 | 90*8 | 10.946 | 140*14 | 29.49 |

| 60*6 | 5.42 | 90*10 | 13.476 | 160*12 | 29.391 |

| 63*4 | 3.907 | 90*12 | 15.94 | 160*14 | 33.987 |

| 63*5 | 4.822 | 100*8 | 12.276 | 160*16 | 38.518 |

| 63*6 | 5.721 | 100*10 | 15.12 | 160*18 | 48.63 |

| 63*8 | 7.7469 | 100*12 | 17.898 | 180*18 | 48.634 |

| 70*5 | 5.397 | 100*14 | 20.611 | 200*24 | 71.168 |

| Unequal Angle Bar | |||||

| Size(mm) | Theoretical Weight (kg/m) |

Size(mm) | Theoretical Weight (kg/m) |

Size(mm) | Theoretical Weight (kg/m) |

| 25*16*3 | 0.912 | 75*50*5 | 5.339 | 110*70*10 | 13.476 |

| 32*20*3 | 1.717 | 75*50*6 | 4.808 | 125*80*8 | 12.551 |

| 40*25*3 | 1.484 | 70*50*7 | 5.699 | 125*80*10 | 15.474 |

| 40*25*4 | 1.936 | 75*50*8 | 7.431 | 125*80*12 | 18.33 |

| 40*28*3 | 1.687 | 80*50*6 | 5.935 | 140*90*8 | 14.16 |

| 40*28*4 | 2.203 | 90*56*6 | 6.717 | 140*90*10 | 17.475 |

| 45*30*4 | 2.251 | 90*56*7 | 7.756 | 140*90*12 | 20.724 |

| 50*32*3 | 1.908 | 90*56*8 | 8.779 | 160*100*10 | 19.872 |

| 50*32*4 | 2.494 | 100*63*6 | 7.55 | 160*100*12 | 23.592 |

| 50*36*3 | 2.153 | 100*63*7 | 8.722 | 160*100*14 | 27.247 |

| 56*36*4 | 2.818 | 100*63*8 | 9.878 | 180*110*10 | 22.273 |

| 56*36*5 | 3.466 | 100*63*10 | 12.142 | 180*110*12 | 26.464 |

| 63*40*4 | 3.185 | 100*80*7 | 9.656 | 180*110*14 | 30.589 |

| 63*40*5 | 3.92 | 100*80*8 | 10.946 | 200*125*12 | 29.761 |

| 63*40*6 | 4.638 | 100*80*10 | 13.476 | 200*125*14 | 34.436 |

| 63*40*7 | 5.339 | 110*70*8 | 10.946 | ||

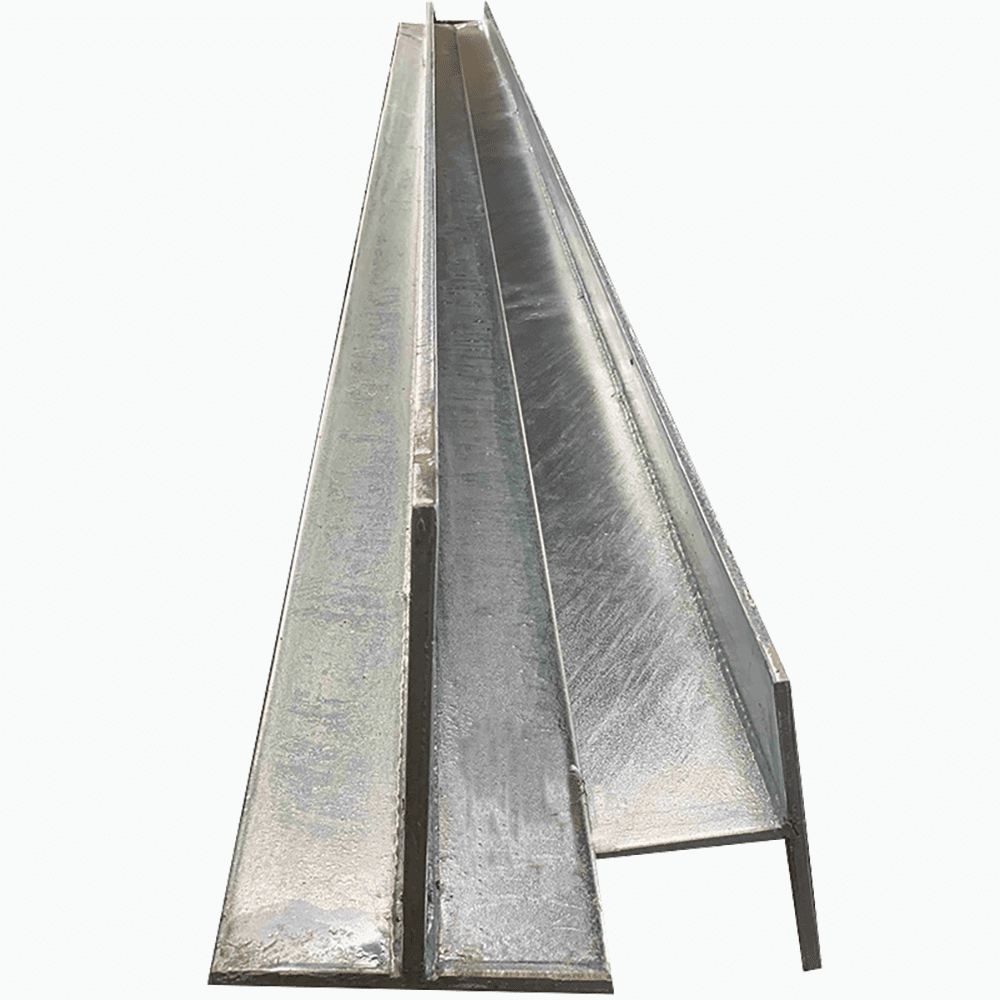

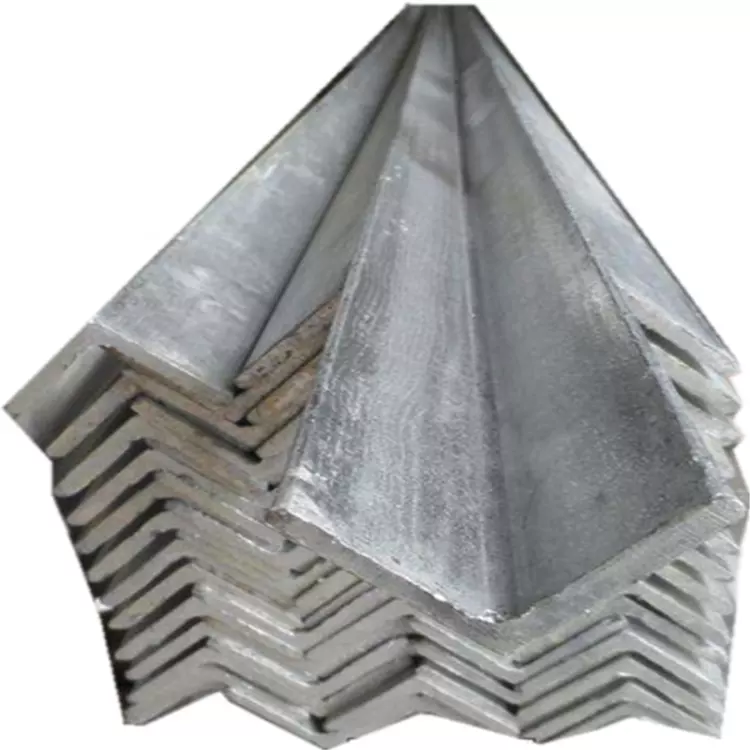

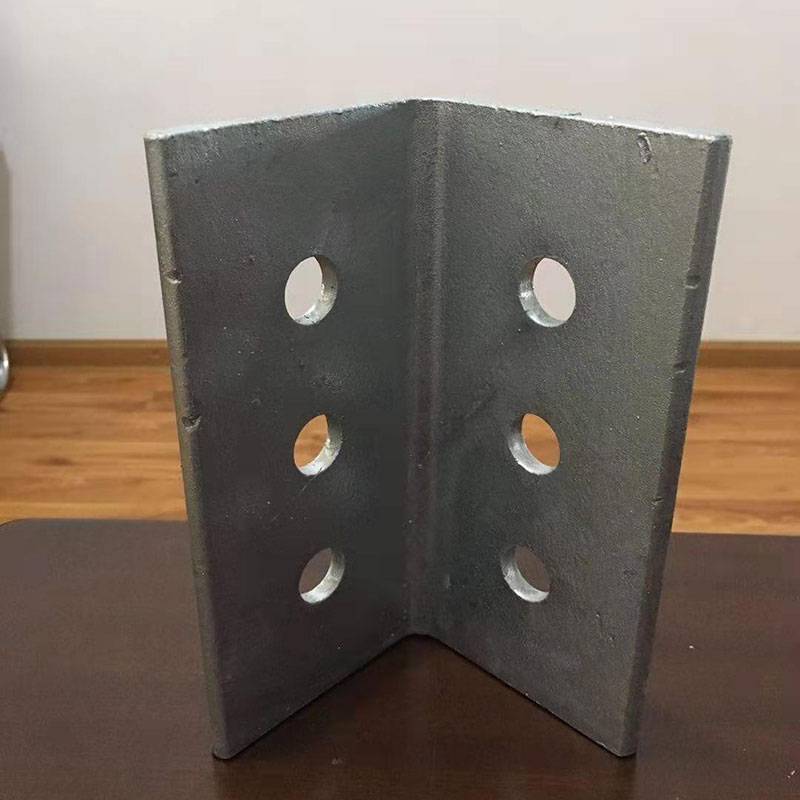

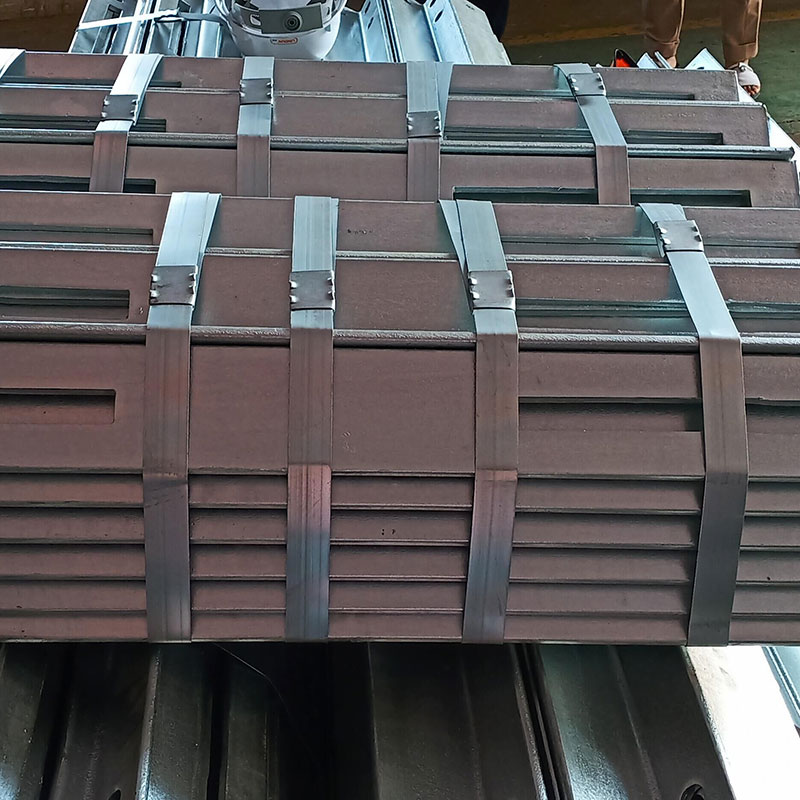

Product Display:

1. Low treatment cost: The cost of hot dip galvanizing is lower than that of other paint coatings.

2. Durable: Hot-dip galvanized angle steel has the characteristics of surface luster, uniform zinc layer, no leakage, no drip-slip, strong adhesion and strong corrosion resistance. In suburban environment, the standard thickness of hot-dip galvanized rust-proof can be maintained for more than 50 years without repair; in urban or offshore areas, the standard thickness of hot-dip galvanized rust-proof layer can be maintained for 20 years. It doesn’t need to be repaired.

3. Good reliability: The galvanized layer is metallurgical bond with the steel and becomes a part of the steel surface, so the durability of the coating is more reliable.

4. The coating has strong toughness: the galvanized layer forms a special metallurgical structure, which can withstand mechanical damage during transportation and use.

5. Comprehensive protection: Every part of the plated part can be galvanized, even in the depression, sharp corner and hidden place can be fully protected;

6. Time-saving and labor-saving: galvanizing process is faster than other coating construction methods, and can avoid the time required for painting on the site after installation.

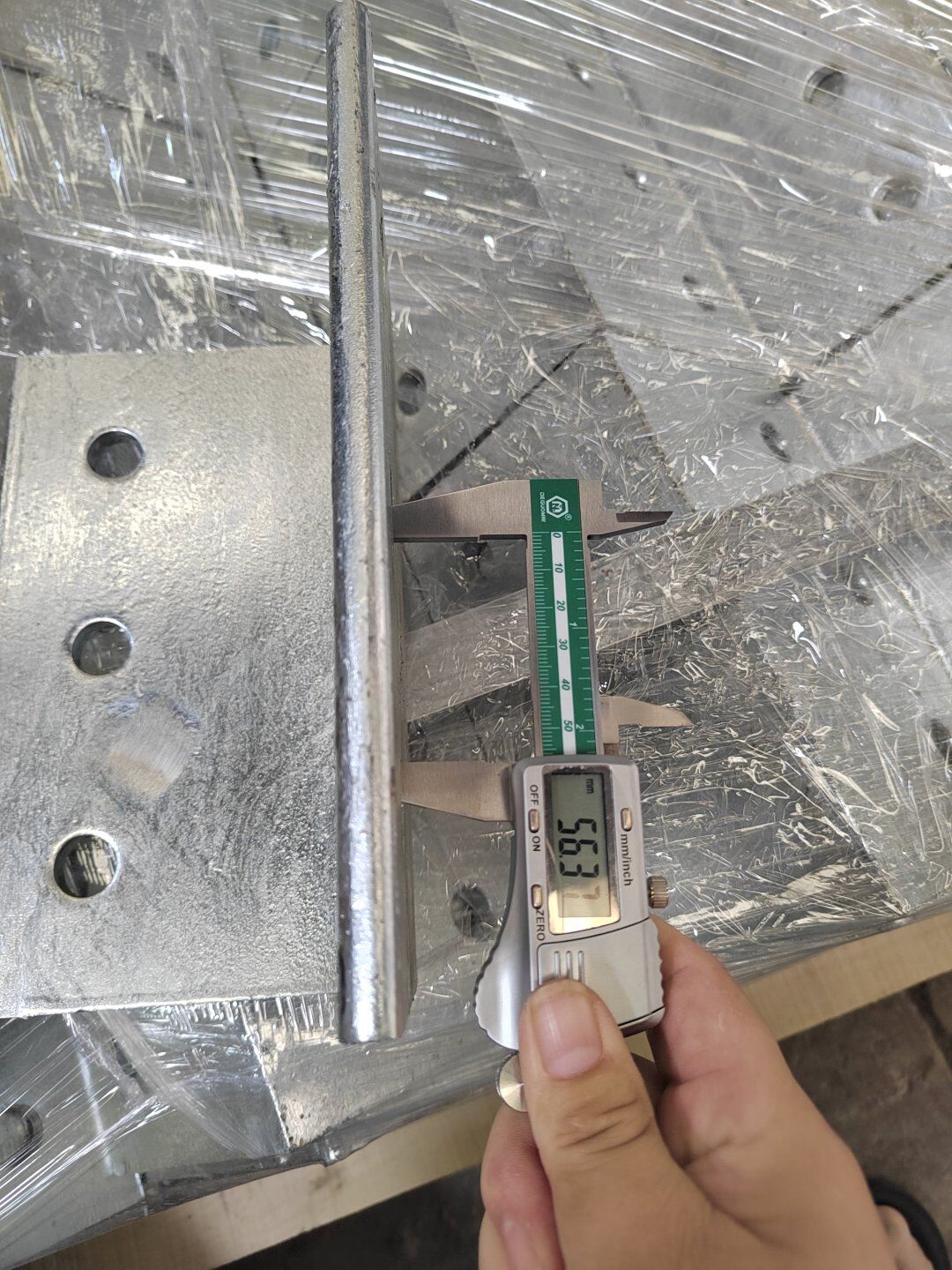

Inspection:

We will use the most precise instrument to test the inner diameter and outer diameter of the hole, measure the wall thickness and the thickness of the zinc layer, and the standard rate is 100%

Product detail pictures:

Related Product Guide:

Steel Deep Processing

Some problems in the construction of steel structure and their solutions

Good quality comes 1st; assistance is foremost; business enterprise is cooperation" is our business enterprise philosophy which is regularly observed and pursued by our company for Slotted Angle Bar - Slotted Metal Angle Bar Angle Bar Metal – Rainbow , The product will supply to all over the world, such as: Oslo, South Africa, Provence, We'd like to invite customers from abroad to discuss business with us. We can provide our clients with high quality products and excellent service. We are sure that we will have good cooperative relationships and make a brilliant future for both parties.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.