Special Shaped Steel Pipe - SSAW – Rainbow

Special Shaped Steel Pipe - SSAW – Rainbow Detail:

Spiral welded pipe is manufactured from steel coil. The coil is unwound and then welded while it is being turned into the shape of the pipe. Changing the angle of the spiral and the thickness of the coil is all that is needed to change from one pipe size to another. The two sides of the double submerged arc weld penetrate the full thickness of the steel to ensure the strength of the finished pipe. Full scale tests have shown that high quality spiral welded pipe is as strong as API pipe. The strength and flexible manufacturing of spiral welded pipe make it the product of choice for a variety of applications.

SSAW Pipe (Spiral Submerged Arc-Welding Pipe), also called HSAW pipe (Helical SAW), welding line shape like a helix. It is using the same welding technology of Submerged Arc-Welding with LSAW pipe.?Manufacturing process is rolling the steel strip, to make the rolling direction have an angle with the direction of the pipe center, forming and welding, so the welding seam is in a spiral line.

| Wall Thickness | 0.4 – 20 mm |

| Thickness Tolerance |

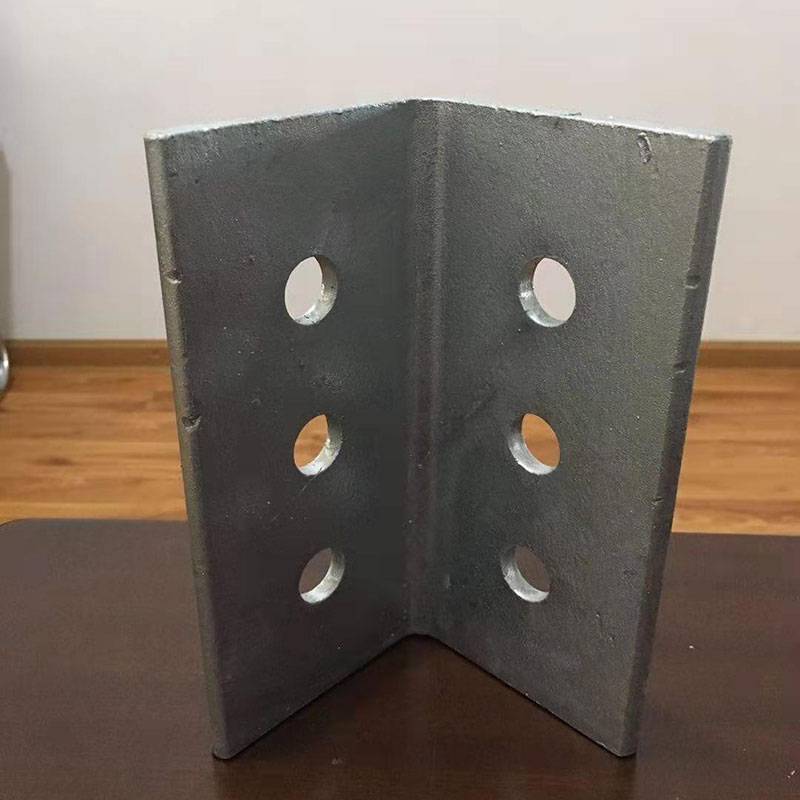

Product detail pictures:

Related Product Guide:

Some problems in the construction of steel structure and their solutions

Greenhouse commonly used steel greenhouse introduction

We have our own sales team, design team, technical team, QC team and package team. We have strict quality control procedures for each process. Also, all of our workers are experienced in printing field for Special Shaped Steel Pipe - SSAW – Rainbow , The product will supply to all over the world, such as: Barcelona, Cologne, Malaysia, By adhering to the principle of "human oriented, winning by quality", our company sincerely welcomes merchants from at home and abroad to visit us, talk business with us and jointly create a brilliant future.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!