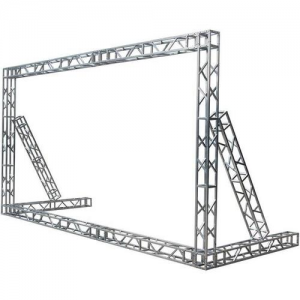

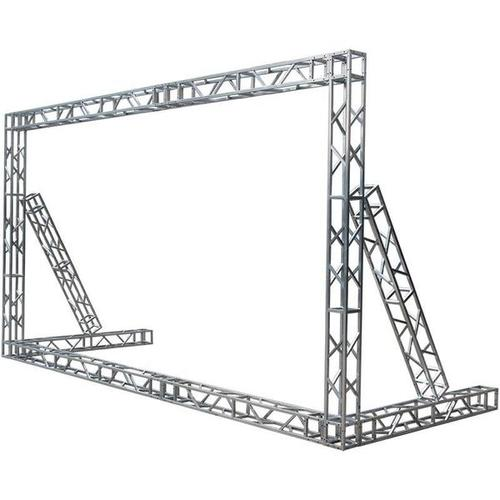

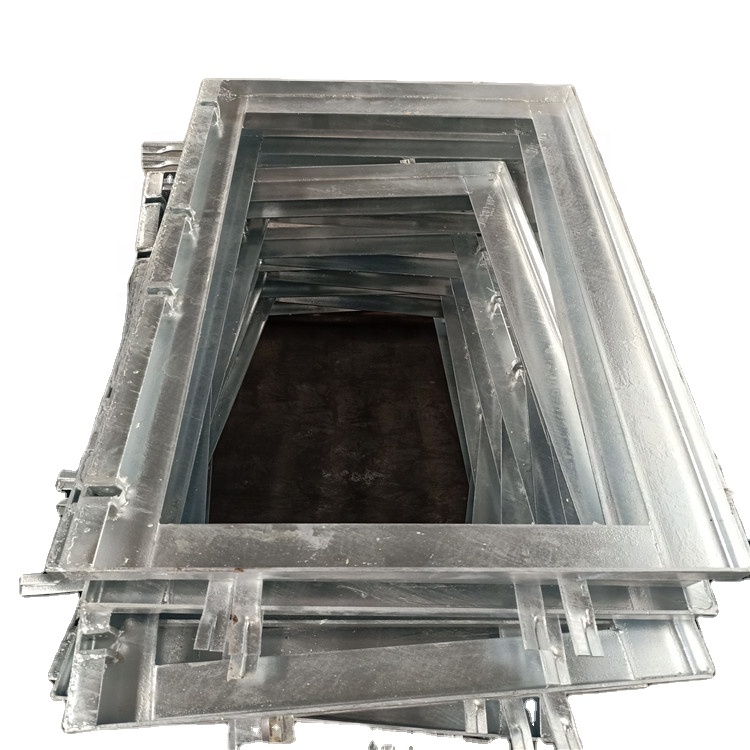

Steel Structure - Welded Steel Frame – Rainbow

Steel Structure - Welded Steel Frame – Rainbow Detail:

Metal furniture USES metal materials, easy to realize processing automation, high degree of mechanization, conducive to improve labor efficiency, reduce product costs, which wood furniture can not be compared.The thin-walled tubes and sheets used in metal furniture can be bent or molded in one go.Create square, round, pointed, flat and other different shapes.Also through the metal material stamping, forging, casting, molding, welding and other processing to obtain different shapes of metal furniture.Not only has the use function, but also can obtain the colorful surface decoration effect through the electroplating, spraying, plastic coating and other processing technology.

|

item

|

Welded steel frame

|

|

Warranty

|

3 years

|

|

After-sale Service

|

Online technical support

|

|

Chemical Composition

|

steel

|

|

Alloy Or Not

|

Non-Alloy

|

|

Secondary Or Not

|

Non-secondary

|

|

Project Solution Capability

|

Others

|

|

Application

|

furniture

|

|

Design Style

|

Modern

|

|

Place of Origin

|

China

|

|

Port of Delivery

|

Tianjin

|

|

Brand Name

|

Rainbow

|

|

Model Number

|

LSF-01

|

|

Product type 1

|

Steel Frame

|

|

Standard

|

BS 1387, BS EN 39, GB/T 3091

|

|

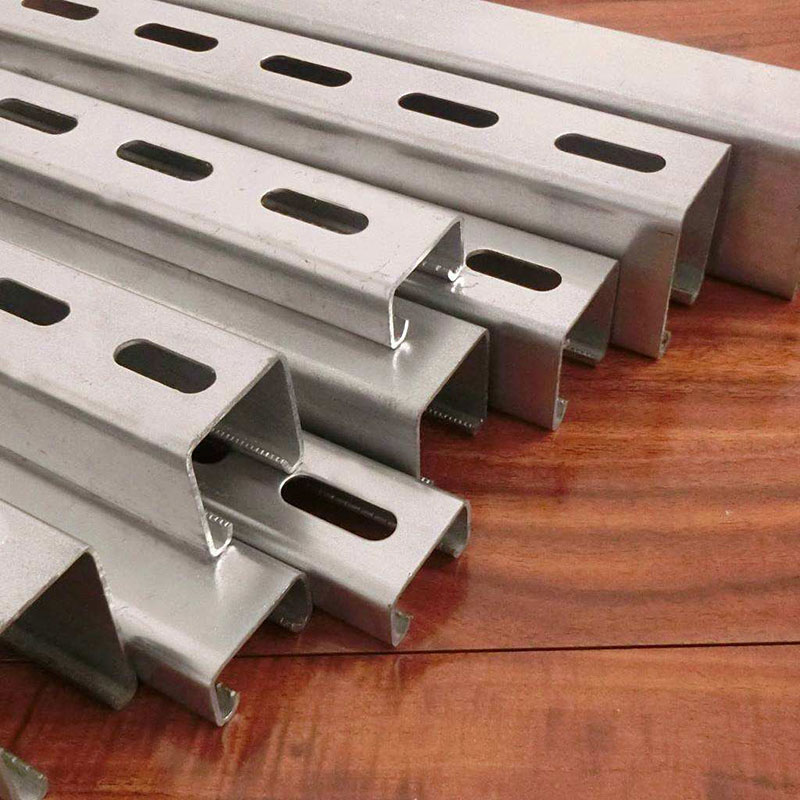

Surface treatment

|

Painted or Powder coated

|

|

Technique

|

Cold Formed

|

|

Package

|

Waterproof package, in bundles or in bulk,

|

|

Raw Material

|

Galvanized Steel

|

|

Usage

|

Furniture, Fence, Structure

|

|

Diameter

|

Per request

|

|

Feature

|

Moisture Resistant

|

|

MOQ

|

10 Ton

|

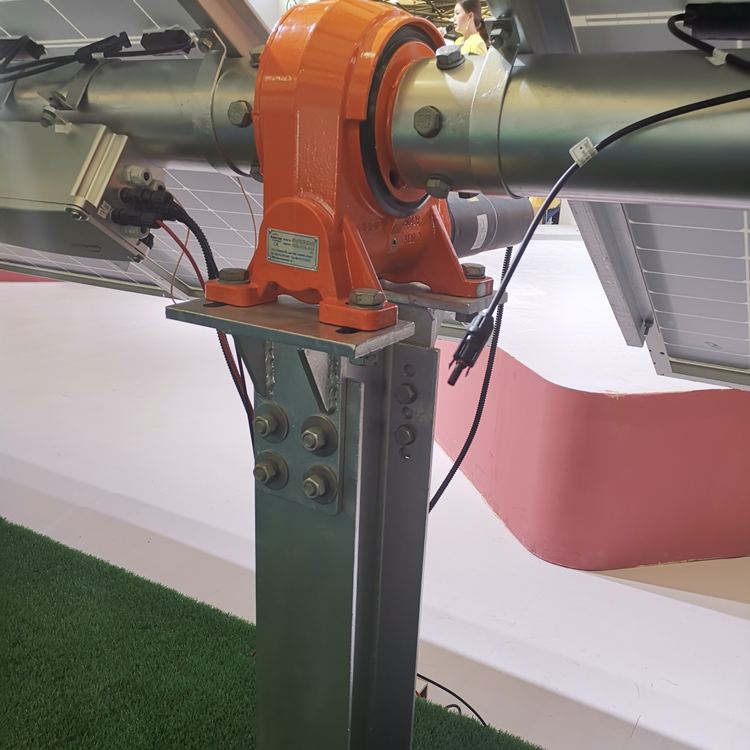

Pipe Cutting

There are four main methods of pipe cutting: cutting, silver cutting, turning cutting, punching cutting, metal lathe cutting parts of the end of the machining precision is relatively high. It is generally used for machining parts of pipes that need to use capacitive energy storage welding, with high production efficiency of punching, but the punch is easy to shrink, and its application area is relatively narrow.

Bending

Bending pipe is generally used in the bracket structure, bending pipe technology refers to the special machine tool, with the help of special equipment to bend the pipe into a circular arc processing technology. Bend pipe is generally divided into hot bend and cold bend.Hot bending is used for pipe with thick wall or solid core, but it is seldom used in metal furniture.Cold bending is formed by bending pressure at room temperature. The commonly used pressure methods include mechanical pressure, hydraulic pressure, manual pressure, etc.

Drilling and punching

General metal parts with screws or rivets combined, the parts must be perforated or punched. Drilling tools generally use bench drill, vertical drill and hand electric drill, sometimes in the design will also be used slot.

Surface treatment

The surface of the parts should be electroplated or coated. There are two kinds of coating methods: spraying metallic paint and electrophoresis paint.

Assembly of components.

After the final correction, the parts are assembled into products with screws and rivets according to different connection modes.

Product detail pictures:

Related Product Guide:

Some problems in the construction of steel structure and their solutions

4 kinds of methods of steel structure interlayer

We consistently carry out our spirit of ''Innovation bringing development, Highly-quality ensuring subsistence, Management promoting benefit, Credit attracting customers for Steel Structure - Welded Steel Frame – Rainbow , The product will supply to all over the world, such as: Sao Paulo, Honduras, Grenada, Welcome to visit our company, factory and our showroom where displays various hair products that will meet your expectation. Meanwhile, it is convenient to visit our website, and our sales staff will try their best to provide you the best service. Please contact us if you need more information. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation.

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.

Write your message here and send it to us